Submersible Pump

Submersible Pump Specification

- Power Rating

- 0.75 kW to 37 kW

- Drive

- Direct

- Operating Temperature

- 5C to 60C

- Connectivity Options

- Direct Cable Connection

- Features

- Corrosion resistant, Energy efficient, Reliable Performance, Easy Installation

- Model No

- Varies as per Model (Consult Manufacturer)

- Machine Type

- Submersible Pump

- Frame Type

- Stainless Steel / Cast Iron

- Motor Power

- Upto 50 HP

- Accuracy

- High

- Lubricating System

- Oil-filled Motor

- Production Capacity

- 500 Units/Month

- Noise Level

- Low (<70 dB)

- Cooling System

- Water Cooled

- Control System

- Start/Stop Control Panel

- Frequency

- 50 Hz/60 Hz

- Voltage

- 220V/380V/440V

- Product Type

- Submersible Pump

- Technology

- Centrifugal Pump Technology

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 1 HP to 50 HP

- Pressure

- Up to 15 Bar

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- Customized as per model

- Weight (kg)

- 18 - 150 kg (as per model)

- Color

- Yellow Blue

- Usage & Applications

- Agricultural, Industrial, Domestic Water Supply, Irrigation, Drainage, Construction Sites

- Bearings

- Heavy Duty Ball Bearings

- Impeller Material

- Stainless Steel / Bronze

- Pump Type

- Multistage / Single-stage

- Discharge Size

- 25 mm to 150 mm

- Maximum Head

- Up to 200 m

- Phase

- Single Phase / Three Phase

- Seal Type

- Mechanical Double Seal

- Suitable Fluids

- Fresh water, Light contaminated water

- Maximum Flow Rate

- Up to 1000 LPM

- Cable Length

- Up to 100 meters

- Shaft Material

- High Strength Stainless Steel

- Protection Class

- IP68

- Working Speed

- 2850 RPM

About Submersible Pump

Versatile Usage and Wide Application Spectrum

Our Submersible Pump is meticulously crafted for applications spanning agricultural irrigation, industrial utilities, domestic water supply, drainage, and construction sites. Its adaptability covers surfaces from open wells to deep reservoirs, matching demanding requirements on fresh water and lightly contaminated water. Unlock reliability and efficiency, whether installed on the farm, in manufacturing facilities, or municipal supply systems, ensuring the right pressure and flow every time.

FOB Port, Payment Terms, and Export Markets Details

Shipped from key Indian FOB ports, our Submersible Pump ensures cost-effective expenditure on logistics and streamlined exchange of goods for global clients. We offer flexible payment terms, including LC, TT, and more, catering to international clients' transaction preferences. The main export markets span Asia, Africa, the Middle East, and Europe, reinforcing our commitment as a reliable distributor, manufacturer, and supplier worldwide.

FAQ's of Submersible Pump:

Q: How does the submersible pump ensure corrosion resistance and reliability?

A: The impeller and frame are constructed using high-grade stainless steel or bronze, complemented by powder coating and mechanical double seals. These features defend against corrosion and deliver long-term, reliable performance even in challenging applications.Q: What fluids and environments are suitable for this submersible pump?

A: This pump is designed for fresh water and light contaminated water, making it ideal for agricultural, industrial, and domestic water supply. Its energy-efficient design holds strong across different mediums and application surfaces such as reservoirs, wells, and drainage systems.Q: When is it recommended to use a multistage versus single-stage pump?

A: Select a multistage pump for high-pressure applications or when a higher head is required (up to 200 meters). Single-stage pumps suit scenarios where lower pressure and shorter head are sufficient. Consult your requirements for optimal selection.Q: Where is the product shipped from, and what are the main export markets?

A: The submersible pump is shipped from primary Indian FOB ports. We serve clients in Asia, Africa, the Middle East, and Europe, facilitating smooth global distribution and support.Q: What is the process for installation, and is it easy to set up?

A: Installation is straightforward, thanks to a direct cable connection, supplied control panel, and compatibility with various well sizes. The pump's design supports quick deployment with minimal downtime.Q: What are the benefits of the water-cooled and oil-filled systems in the pump?

A: Water cooling ensures efficient operation within a 5C to 60C range, while the oil-filled motor provides superior lubrication, extending the pump's service life and boosting performance reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

Mud Pump

Surface Treatment : Other, Paint Coated

Power Source : Other, Electric

Technology : Other, Threecylinder Singleacting

Product Type : Other, Reciprocating Positive Displacement Pump

Operating Type : Automatic

SS Centrifugal Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Power Source : Electricity

Technology : Other

Product Type : Other

Operating Type : Semi Automatic

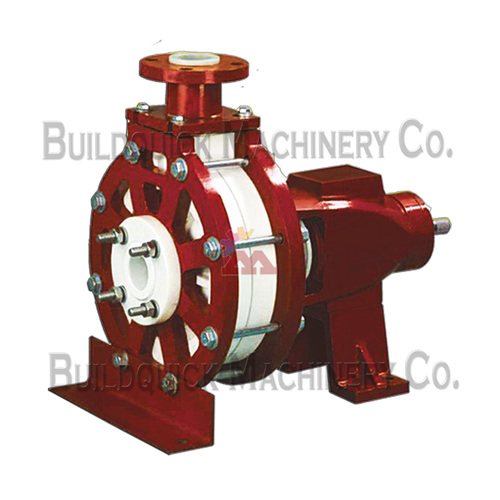

Corrosion Resistant Polypropylene Centrifugal Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Power Source : Electricity

Technology : Other

Product Type : Other

Operating Type : Semi Automatic

High speed Low Duty Sewage And Effluent Submersible Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Power Source : Electricity

Technology : Other

Product Type : Other

Operating Type : Semi Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS