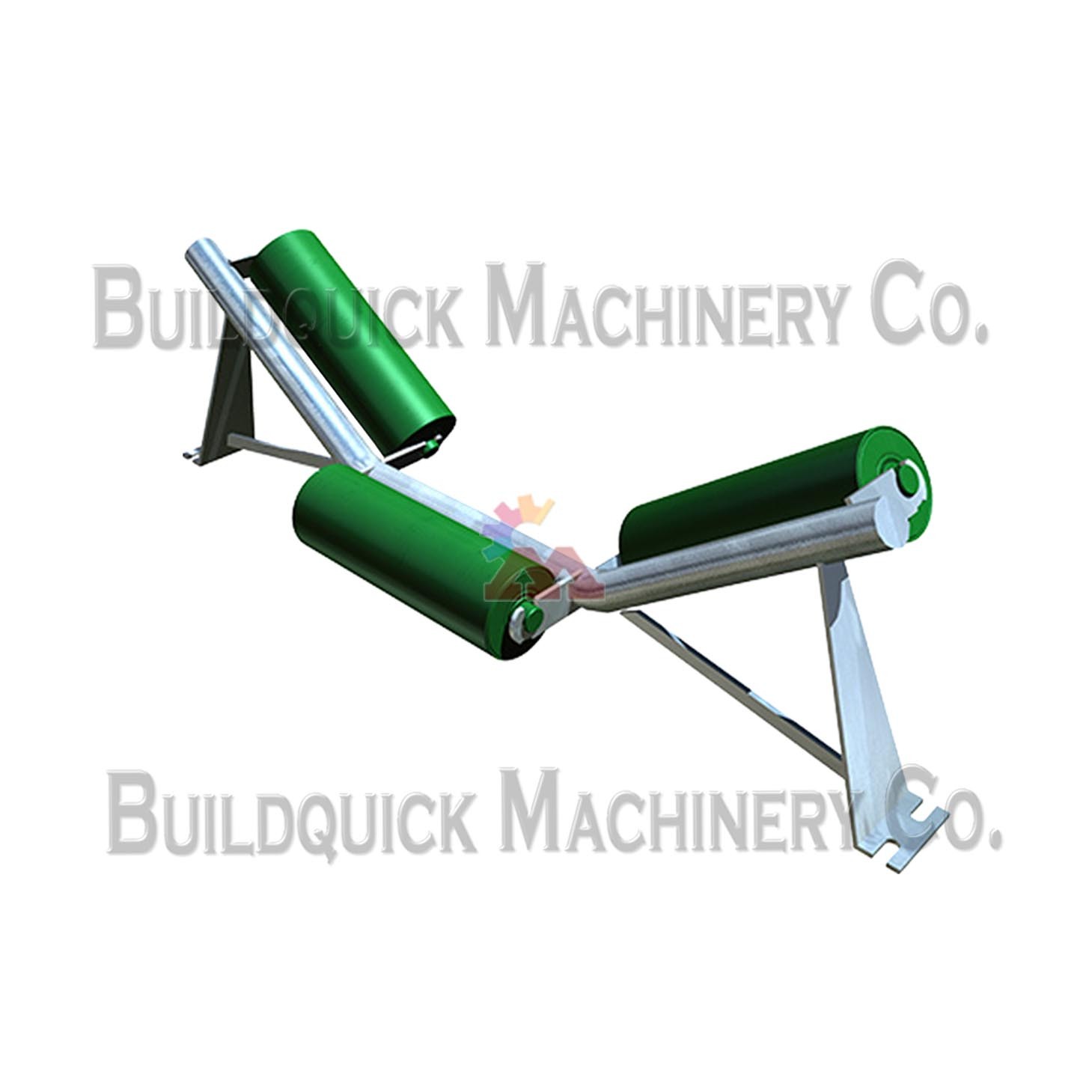

Roller Conveyor

Price 500 INR/ Piece

MOQ : 1 Box Unit

Roller Conveyor Specification

- Shape

- Rectangular Frame

- Phase

- Single/Three Phase (for Powered Version)

- Diameter

- 50 mm (Standard Roller Diameter)

- Torque

- As per Motor Specification (for Powered Version)

- Product Type

- Roller Conveyor

- General Use

- Material Handling/Industrial Automation

- Material

- Mild Steel (MS), Stainless Steel (SS)

- Type

- Gravity or Powered Roller Conveyor

- Capacity

- Up to 200 kg/m (varies as per design)

- Weight (kg)

- 120-350 kg (varies by model and length)

- Computerized

- No

- Automatic

- Optional (Manual or Motorized)

- Touch Screen

- No

- Control System

- Centralized/Manual

- Surface Treatment

- Powder Coated/Galvanized

- QC System

- ISO 9001:2015

- Tolerance

- ±0.5 mm

- Drawing

- Available on Request

- Voltage

- 220V/380V (For Motorized)

- Dimension (L*W*H)

- Customizable (e.g. 2000x800x700 mm)

- Feature

- Corrosion Resistant, High Load Capacity, Wear Resistant Rollers

- Color

- Silver, Blue, or Custom

- Safety

- Guard rails optional

- Load Per Roller

- Up to 50 kg (depending on roller spec)

- Mounting

- Floor Mounted/Adjustable Height

- Roller Pitch

- 100-150 mm

- Installation

- Easy Bolt-Together

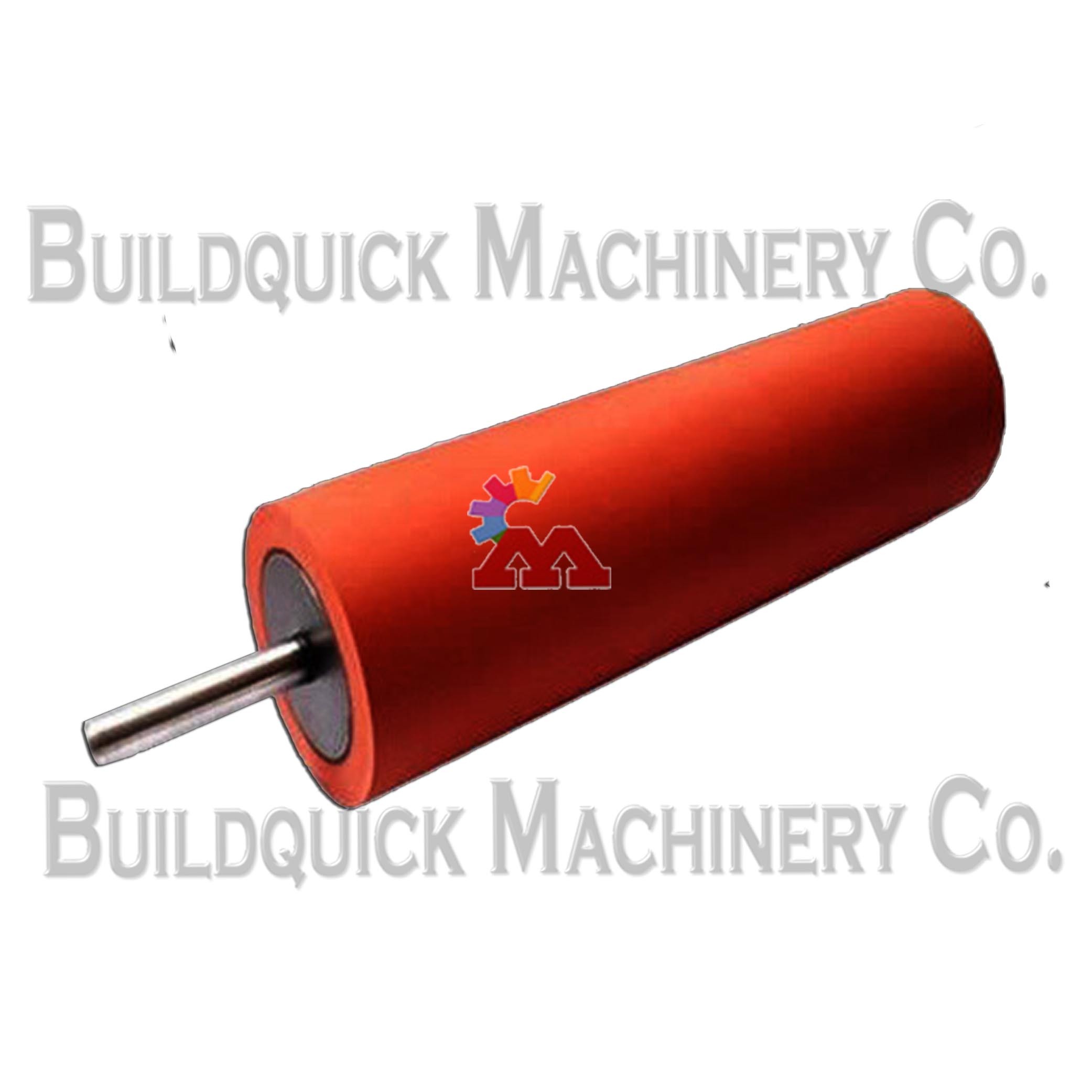

- Bearing Type

- Sealed Ball Bearing

- Ambient Temperature Range

- -10°C to +60°C

- Noise Level

- Low

- Roller Material

- Galvanized Steel / Stainless Steel

- Customization

- Available as per requirements

- Length

- 1 meter up to 10 meters (standard/custom)

- Conveyor Speed

- Up to 30 m/min (for powered)

- Frame Material

- Mild Steel Channel / SS304

About Roller Conveyor

Experience ravishing material handling efficiency with our top-rated Roller Conveyor system, designed for first-rate performance across industrial environments. Featuring remarkable value, this conveyor comes in standard/custom lengths from 1 to 10 meters, with roller pitch of 100-150 mm. Crafted from corrosion-resistant galvanized or stainless steel, the sealed ball bearing rollers boast up to 50 kg load capacity each, and the frame is built with powder coated MS or SS304. The easy bolt-together installation, low noise, and customizable options ensure optimal savings, adaptability, and reliability. Ideal for material handling and automation, this conveyor delivers a truly remarkable solution for India's leading distributors, manufacturers, and service providers.

Innovative Roller Conveyor Features & Industrial Applications

Our Roller Conveyor offers impressive advantages-including high load capacity, wear-resistant rollers, and flexible dimensions for customized setups. Users benefit from adjustable mounting options, corrosion-resistant materials, and low noise operation. Ideal for demanding material handling and industrial automation environments, it ensures precision and efficiency across sectors. The conveyor's versatile design accommodates gravity and powered versions, making it perfect for distribution centers, assembly lines, warehouses, and packaging surfaces.

Certifications, Proposal & Export Markets

Certified under ISO 9001:2015 for quality assurance, our roller conveyors are shipped goods with an estimated delivery time depending on proposal amount and order specifications. We cater to major export markets including South Asia, Middle East, and Africa. Each order comes with detailed drawings upon request, guaranteeing clear communication and optimal performance. Our commitment to best practices and customer satisfaction ensures secure, timely delivery across global industrial landscapes.

Innovative Roller Conveyor Features & Industrial Applications

Our Roller Conveyor offers impressive advantages-including high load capacity, wear-resistant rollers, and flexible dimensions for customized setups. Users benefit from adjustable mounting options, corrosion-resistant materials, and low noise operation. Ideal for demanding material handling and industrial automation environments, it ensures precision and efficiency across sectors. The conveyor's versatile design accommodates gravity and powered versions, making it perfect for distribution centers, assembly lines, warehouses, and packaging surfaces.

Certifications, Proposal & Export Markets

Certified under ISO 9001:2015 for quality assurance, our roller conveyors are shipped goods with an estimated delivery time depending on proposal amount and order specifications. We cater to major export markets including South Asia, Middle East, and Africa. Each order comes with detailed drawings upon request, guaranteeing clear communication and optimal performance. Our commitment to best practices and customer satisfaction ensures secure, timely delivery across global industrial landscapes.

FAQ's of Roller Conveyor:

Q: How is the roller conveyor customized to suit diverse material handling needs?

A: Customizations are available for length, roller pitch, frame material, mounting type, and overall dimensions. These can be tailored to meet specific workflow requirements, load capacities, and installation settings.Q: What is the process for installation of the roller conveyor system?

A: Installation is simplified by the bolt-together design. Most systems can be assembled quickly on-site with basic tools. Detailed assembly manuals and drawings are provided for efficient setup.Q: When can customers expect delivery after placing an order?

A: Estimated delivery times vary depending on the proposal amount, order size, and customization requirements. Usually, goods are shipped within the mutually agreed timeline specified during the order proposal stage.Q: Where can these roller conveyors be effectively used?

A: They are ideally suited for material handling, industrial automation, packaging, warehouses, distribution centers, and assembly lines, thanks to their flexibility and robust build.Q: What advantages do powered roller conveyors offer over manual versions?

A: Powered conveyors enable higher transport speeds (up to 30 m/min), improved efficiency, and centralized or manual control systems, while manual gravity conveyors offer cost savings and reduced electrical dependency.Q: How do sealed ball bearings enhance the conveyor's performance?

A: Sealed ball bearings ensure smooth, maintenance-free operation, reducing wear and enabling quiet movement even under high load conditions. This enhances productivity and longevity of the conveyor system.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS