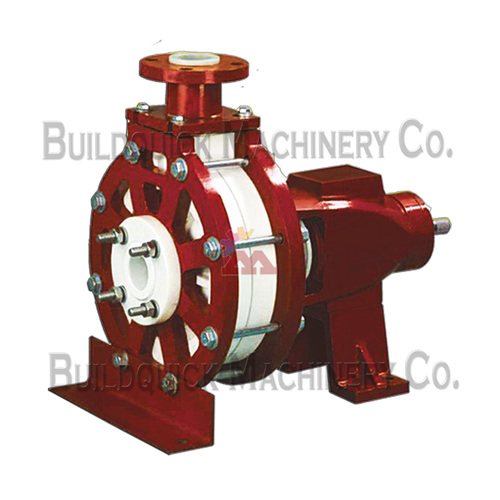

Corrosion Resistant Polypropylene Centrifugal Pump

Corrosion Resistant Polypropylene Centrifugal Pump Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Pressure

- Up to 4.5 kgf/cm2

- Surface Treatment

- Other

- Production Capacity

- Up to 50 m3/hr

- Usage & Applications

- Water Treatment Plant, Effluent Treatment Plant, Electro Planting, Pickling & Steel Rolling mills, Excellent for Transfer & Loading - Unloading Like HCL,Sulphuric acid/Alkali, Caustic Liquid, Scrubbing of Corrosive Gases like Co2,So3,So2,I2,F2,Br2,CI2,Etc... For Handling Liquids in Various Industry link Textiles, Paper, Cellulose, Sugar, Steel, Food Having Temperature Range Materials, Etc... Ideal for Circulation of Pickling line & Scrubbing in Steel Plants.High Capacity Transfer Pump, Filter press for Dyes & Chemicals, Descaling, Oil & Other Fuels.

Corrosion Resistant Polypropylene Centrifugal Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Corrosion Resistant Polypropylene Centrifugal Pump

| MP PP Corrosion Resistant Polypropyline Centrifugal Pump | ||

| 1 | Capacity | Up to 50M^3/Hr |

| 2 | Head | Up to 45Mtr |

| 3 | Temperature | 80 |

| 4 | Speed | Up to 3500Rpm |

| 5 | Discharge size | 25mm to 50mm |

| 6 | Pressure | Up to 4.5 Kg/cm^2 |

| 7 | M.O.C. | PP,UHMWPE |

| 8 |

|

|

Advanced Corrosion Resistance for Harsh Environments

Constructed with high-grade polypropylene, this centrifugal pump excels in corrosive and acidic conditions. Its robust design ensures long operational life and minimal maintenance, making it an optimal choice for chemical processing, metal finishing, and fuel transfer applications, even where exposure to sulfuric acid, hydrochloric acid, or caustic liquids is common.

Versatile Industrial Applications

This pump supports numerous industry sectors, from water treatment plants to steel and textile industries, and is ideal for tasks such as pickling line circulation, scrubbing corrosive gases, and descaling operations. Its broad temperature handling capability and compatibility with diverse fluids enable high capacity transfer, filtration, and loading tasks with enhanced safety and efficiency.

Semi-Automatic Operation for Increased Efficiency

The semi-automatic operating system integrates reliable control with reduced manual intervention, boosting productivity and ensuring consistent performance. Its design enables ease of monitoring and seamless integration with industrial processes, making it a preferred solution for continuous or batch operations in demanding environments.

FAQ's of Corrosion Resistant Polypropylene Centrifugal Pump:

Q: How does the corrosion resistant polypropylene centrifugal pump benefit industrial chemical handling?

A: This pump's polypropylene construction provides exceptional resistance against corrosive chemicals, such as acids, alkalis, and caustic liquids. It ensures safe and efficient transfer, loading, and unloading processes, thereby reducing maintenance costs and extending equipment life when handling aggressive fluids like HCL and sulphuric acid.Q: What industries commonly use this centrifugal pump, and for which applications?

A: Industries including water treatment, effluent treatment, electroplating, pickling, steel rolling mills, textiles, paper, sugar, cellulose, and food processing rely on this pump for tasks like transferring chemicals, filtration, pickling line circulation, scrubbing corrosive gases, descaling, and handling fluids at varied temperature ranges.Q: Where can the pump be installed for optimal performance?

A: The pump is suited for installation in chemical transfer stations, water or effluent treatment facilities, steel and pickling lines, acid loading/unloading bays, and filtration setups in various manufacturing units across India. Proper installation ensures reliable operation and maximizes its corrosion-resistant properties.Q: What is the process for operating the semi-automatic centrifugal pump?

A: Operation involves connecting the pump to an electric power source, configuring the desired flow and pressure settings, and monitoring performance through integrated control panels. Its semi-automatic functions streamline start-up, transfer, and shut-down processes, making it user-friendly for industrial operators.Q: When is it ideal to use polypropylene centrifugal pumps over metal alternatives?

A: Polypropylene pumps are preferred when handling highly corrosive liquids, strong acids, or alkalis, especially when metal pumps risk rapid degradation. Use these pumps for applications where chemical compatibility and long-term durability are critical requirements.Q: What are the safety advantages during transfer and scrubbing of corrosive gases?

A: The pump's non-metallic, corrosion-resistant construction minimizes the risk of leaks and chemical reactions, protecting both equipment and personnel in environments where gases like CO2, SO3, SO2, Cl2, Br2, and I2 are handled. Enhanced safety features reduce exposure and improve containment for hazardous compounds.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

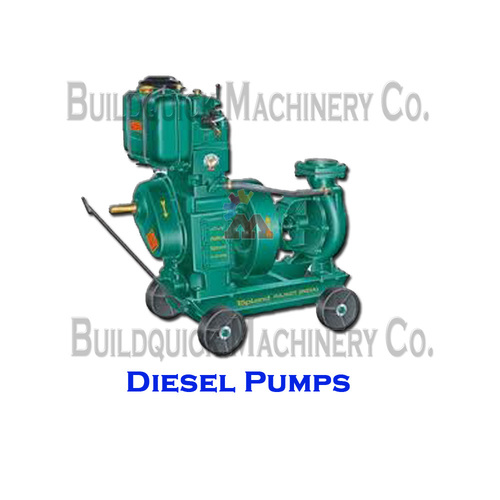

Diesel Pump

Minimum Order Quantity : 5 Pieces

Usage & Applications : Fuel transfer, irrigation, industrial fluid dispensing

Technology : Other

Surface Treatment : Other, Powder Coated

Operating Type : Semi Automatic

Production Capacity : 1200 Liters/hour

Mud Pump

Usage & Applications : Drilling mud circulation in oilfield and mining

Technology : Other, Threecylinder Singleacting

Surface Treatment : Other, Paint Coated

Operating Type : Automatic

Production Capacity : 45 m/h

MP GD Dewatering Submersible Pump

Minimum Order Quantity : 1 Piece

Usage & Applications : "Muddy Water Transfer, Effluent transfer, ETP,STP, Waste Treatment plant, Hotel, Hospital, Railway, Dairy, Power Plant, Chemical Industries, Sugar, Steel,Cement, Food Beverages,Civil Construction Deeatering Foundations, Trenches & Pits,Punlic utilities,ETC.."

Technology : Other

Surface Treatment : Other

Operating Type : Semi Automatic

Production Capacity : Up to 132 m3/hr

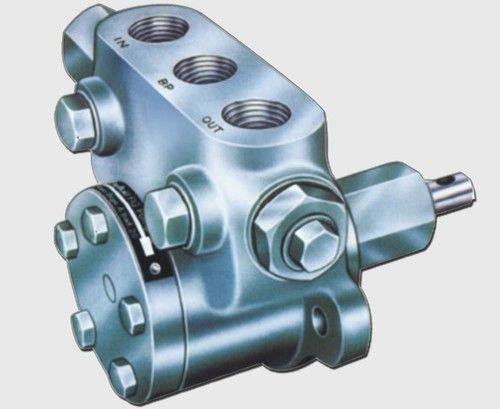

Injection Internal Gear Pump

Minimum Order Quantity : 1 Piece

Usage & Applications : Oil Burners, Boilers, Hydraulic Dry Pressure Pumps, Lubrication oil, Hydraulic oil, PHF Units, Filter Bowstring, Diesel in Locomotives, Petroleum Industries, Force feed Lubrication, Pressure Regulator.

Technology : Other

Surface Treatment : Other

Operating Type : Semi Automatic

Production Capacity : Up to 360 m3/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS