SS Centrifugal Pump

SS Centrifugal Pump Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 415V,3Phase/215V,1 Volt (v)

- Surface Treatment

- Other

- Production Capacity

- Up to 90 m3/hr

- Usage & Applications

- Milk, Cream, Butter milk, Condensed Milk, Fruit Juice, Sugar Syrup, Vitamin Solution, Beer,Wine, Vegetable, Oil, Mineral Oil, Lubricating Oil, Alkaline Solution, Acids Fine Chemicals, Colour Dyes & Pigments, R.O. Water, DM Water & Pure Water, Dairy Industries, Pharmaceutical Industries, Food Industries, Textile, Paper & Cement Industries. Mono/Bare Pumps are available. Bare Pump are also Available with flame proof

SS Centrifugal Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About SS Centrifugal Pump

| MP CFS Centrifugal Sanitary Design Dairy Pharmaceutical Pump | ||

| 1 | Capacity | Up to 90M3/Hr |

| 2 | Head | Up to 60Mtr |

| 3 | Hp | Up to 20Hp |

| 4 | Speed | 2800/1450Rpm |

| 5 | Connection | Dol, Star Delta |

| 6 | Voltage & Phase | 415V 3Phase/215V 1Phase |

| 7 | Mechanical Seal | Mechanical Seal (SIC/ SIC or TC/TC) |

| 8 | M.O.C. |

|

| 9 | Application |

|

Wide Application Range

The SS Centrifugal Pump is engineered for versatile use in dairy, food, pharmaceutical, textile, paper, and cement industries. It efficiently handles various liquids such as milk, fruit juice, chemicals, oils, and pure water, providing reliable performance across standard and specialized applications.

High Efficiency and Flexible Power Options

Designed for high productivity, this pump works seamlessly at both 415V (3 phase) and 215V (single phase) electrical supply, delivering up to 90 m3/hr output. Its semi-automatic operation ensures consistent liquid transfer while minimizing manual intervention.

Durability and Specialized Features

Constructed with stainless steel, the pump offers strength and corrosion resistance. Mono and bare pumps-including flame proof variants-are available to meet specific industry standards and safety requirements. Sourcing and custom configurations can be facilitated through vendors across India.

FAQ's of SS Centrifugal Pump:

Q: How does the SS Centrifugal Pump enhance operational efficiency in industrial applications?

A: The pump provides high throughput with up to 90 m3/hr capacity while supporting a broad spectrum of fluids, minimizing downtime and boosting process speed in operations like dairy, pharmaceuticals, and food processing.Q: What types of liquids can be processed with this pump?

A: It is designed to handle milk, cream, buttermilk, condensing fluids, fruit juice, sugar syrup, oils, chemicals, alkaline solutions, acids, dyes, and various forms of water including RO, DM, and pure water.Q: When should I opt for flame proof bare pump variants?

A: Flame proof bare pumps are recommended for environments where flammable or hazardous fluids are processed, such as chemical plants or areas with strict safety regulations.Q: Where can this pump be installed within a plant or factory setup?

A: The pump's compact and adaptable design allows it to be installed at critical transfer points in process lines for industries like dairy, food, pharmaceuticals, textiles, paper, and cement.Q: What is the process of sourcing or ordering the SS Centrifugal Pump in India?

A: You can procure the pump through authorized distributors, manufacturers, suppliers, or service providers. They can also advise on the best model and customization for your specific requirements.Q: How do mono and bare pump versions differ in usage?

A: Mono pumps are generally self-contained units ready for direct installation, while bare pumps provide more flexibility for integration with existing systems or customization, including flame proof options for higher safety needs.Q: What are the main benefits of using a stainless steel centrifugal pump in industrial operations?

A: Stainless steel construction ensures durability, corrosion resistance, hygienic processing, and long operational life, making the pump ideal for demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

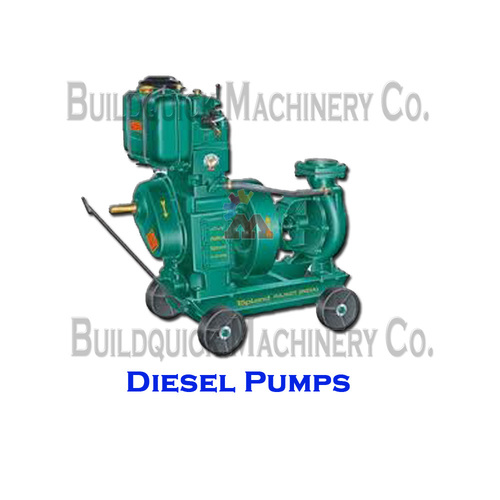

Diesel Pump

Minimum Order Quantity : 5 Pieces

Surface Treatment : Other, Powder Coated

Power Source : Diesel

Operating Type : Semi Automatic

Usage & Applications : Fuel transfer, irrigation, industrial fluid dispensing

Production Capacity : 1200 Liters/hour

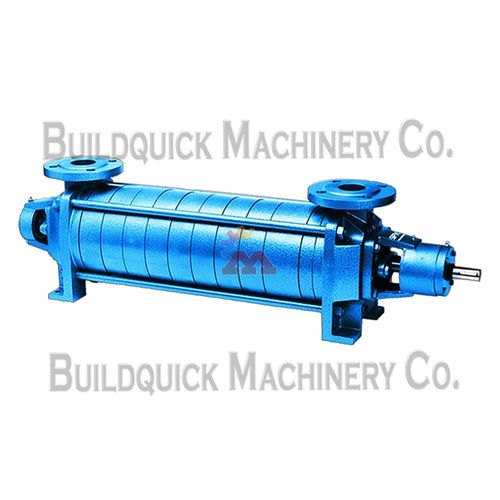

Centrifugal High Pressure Multi Stage Pumps

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Power Source : Electricity

Operating Type : Semi Automatic

Usage & Applications : Condensate Water Transfer, Sprinkler irrigation or Water Supply in Hilly Area ,Fire Fighting System, Water supply high Rise Building, Mine Dewatering, Boiler feeds, Reverse Osmosis. Condensate Extraction. Booster Plants. Hot & Cooling Water Circulating. High pressure for Hydraulic pressure. Filter press Washing,Power Plant

Production Capacity : Up to 80 m3/hr

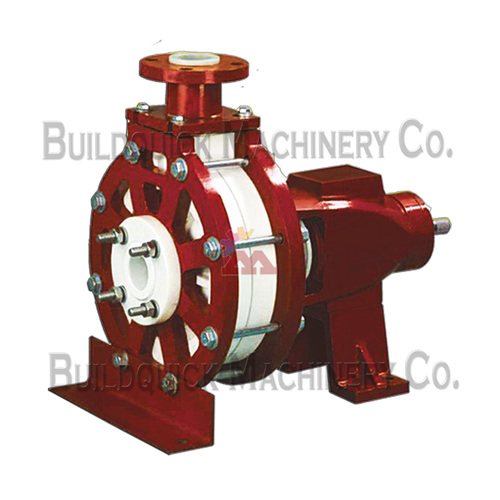

Corrosion Resistant Polypropylene Centrifugal Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Power Source : Electricity

Operating Type : Semi Automatic

Usage & Applications : Water Treatment Plant, Effluent Treatment Plant, Electro Planting, Pickling & Steel Rolling mills, Excellent for Transfer & Loading Unloading Like HCL,Sulphuric acid/Alkali, Caustic Liquid, Scrubbing of Corrosive Gases like Co2,So3,So2,I2,F2,Br2,CI2,Etc... For Handling Liquids in Various Industry link Textiles, Paper, Cellulose, Sugar, Steel, Food Having Temperature Range Materials, Etc... Ideal for Circulation of Pickling line & Scrubbing in Steel Plants.High Capacity Transfer Pump, Filter press for Dyes & Chemicals, Descaling, Oil & Other Fuels.

Production Capacity : Up to 50 m3/hr

MP GD Dewatering Submersible Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Power Source : Electricity

Operating Type : Semi Automatic

Usage & Applications : "Muddy Water Transfer, Effluent transfer, ETP,STP, Waste Treatment plant, Hotel, Hospital, Railway, Dairy, Power Plant, Chemical Industries, Sugar, Steel,Cement, Food Beverages,Civil Construction Deeatering Foundations, Trenches & Pits,Punlic utilities,ETC.."

Production Capacity : Up to 132 m3/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS