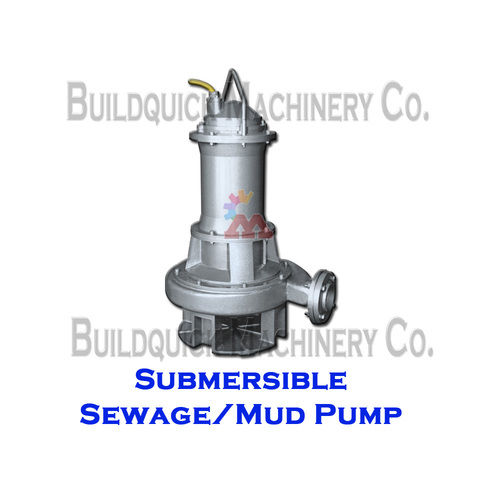

High speed Low Duty Sewage And Effluent Submersible Pump

High speed Low Duty Sewage And Effluent Submersible Pump Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Pressure

- Up to 15 kgf/cm2

- Surface Treatment

- Other

- Production Capacity

- Up to 350 m3/hr

- Usage & Applications

- Organic/Inorganic Chemicals, Caustic Process, Effluent, Filter Press, Slurry Application, Volatile Liquid, Corrosive Chemical, Pharmaceutical dyes, Textile, Kerosene Plant, Fertilizer, cement & Steel Industries, Wate Water Treatment Plant, Effluent transfer, ETP, STP, For Pumping Chemicals with solid in suspension polluted liquids,Widely used for Public & Civil Engineering, Paper & Pulp Industries,Hot and cold water

High speed Low Duty Sewage And Effluent Submersible Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About High speed Low Duty Sewage And Effluent Submersible Pump

| MP CIC Centrifugal Process Pump in investment casting | ||

| 1 | Capacity | Up to 350M^3/Hr |

| 2 | Head | Up to 150Mtr |

| 3 | Temperature | 250 |

| 4 | Speed | Up to 3500Rpm |

| 5 | Discharge size | 25mm to 100mm |

| 6 | Pressure | Up to 15 Kg/cm^2 |

| 7 | M.O.C. |

|

|

|

|

Robust Design for Demanding Applications

Crafted for durability, the submersible pump effectively manages corrosive and volatile liquids, effluents, slurries, and chemical wastes. Its engineered structure allows operation in challenging environments like fertilizer, cement, steel plants, and wastewater facilities. Pump components are built for sustained performance in both hot and cold water conditions.

Versatile and Efficient Operation

The pump's semi-automatic operating type ensures flexibility, making it suitable for continuous or intermittent usage. It simplifies processes in filter presses, effluent and chemical transfer, and slurry handling, providing reliable service in public infrastructure projects and heavy industries. Production capacity reaches up to 350 m3/hr with consistent pressure across applications.

FAQ's of High speed Low Duty Sewage And Effluent Submersible Pump:

Q: How does the High Speed Low Duty Submersible Pump handle chemicals with solids in suspension?

A: The pump features a design suited for moving liquids contaminated with solid particles, such as chemical slurry and polluted wastewater. Its robust impeller and construction ensure efficient pumping without clogging or breakdown, delivering reliable performance across difficult fluid conditions.Q: What industries commonly use this submersible pump in India?

A: This pump is widely used in fertilizer, cement, steel, textile, pharmaceutical, paper and pulp, public and civil engineering, and wastewater treatment plants. These sectors benefit from its ability to process corrosive, volatile, and effluent materials efficiently.Q: When is it recommended to use this pump for effluent transfer?

A: This pump is ideal for both routine and emergency effluent transfers in wastewater treatment plants (ETP/STP) and industrial processes requiring pollution control. Its high flow capacity and pressure rating make it suitable for meeting production and environmental compliance needs.Q: Where can this pump be installed in an industrial setting?

A: It can be installed in sumps, tanks, pits, or directly in process streams across manufacturing, chemical, and wastewater plants. Submersible design allows efficient usage in submerged locations, minimizing footprint and maximizing fluid movement flexibility.Q: What is the process for maintaining the pump's performance?

A: Routine cleaning, periodic inspection of impeller and seals, and proper electrical safety checks are essential to maintain optimal performance. As a semi-automatic unit, it requires minimal manual intervention and is supported by service providers and manufacturers for maintenance needs.Q: How does using this pump benefit public and civil engineering projects?

A: The pump offers quick and reliable disposal of wastewater, effluents, and contaminated liquids, supporting efficient water management and pollution control in public infrastructure, construction projects, and municipal services.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

Mud Pump

Production Capacity : 45 m/h

Product Type : Other, Reciprocating Positive Displacement Pump

Operating Type : Automatic

Surface Treatment : Other, Paint Coated

Power Source : Other, Electric

Submersible Pump

Production Capacity : 500 Units/Month

Product Type : Other, Submersible Pump

Operating Type : Automatic

Surface Treatment : Other, Powder Coated

Power Source : Other, Electric

MP GD Dewatering Submersible Pump

Minimum Order Quantity : 1 Piece

Production Capacity : Up to 132 m3/hr

Product Type : Other

Operating Type : Semi Automatic

Surface Treatment : Other

Power Source : Electricity

Submersible Sewage Mud Pump (MP GS HD)

Minimum Order Quantity : 1 Piece

Production Capacity : Up to 2000 m3/hr

Product Type : Other

Operating Type : Semi Automatic

Surface Treatment : Other

Power Source : Electricity

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS