Hydro Testing Pump

Hydro Testing Pump Specification

- Machine Type

- Hydro Testing Pump

- Features

- Durable Efficient High-Pressure Testing

- Pressure

- High Pressure

- Color

- Green

- Usage & Applications

- Hydrostatic Testing for pipes tubes and vessels

About Hydro Testing Pump

Versatile Applications and Superior Features

Our Hydro Testing Pump stands out for its adaptable usage across numerous industries, including testing pipes, tubes, pressure vessels, and more. Beyond hydrostatic verification, it's relied upon for leak testing and integrity assessment in construction and manufacturing sectors. Core features include exceptional durability, energy-efficient operation, and consistently high-pressure performance. Other notable qualities are its compact design, ease of maintenance, and compatibility with a broad range of testing fluids, reinforcing its position as an unrivaled industry tool.

Efficient Delivery, Ample Supply, and Sample Options

Our Hydro Testing Pump is available for timely dispatch with prompt freight arrangements catering to diverse domestic markets in India. We ensure rapid fulfillment, courtesy of our robust supply ability that keeps outlay in check and streamlines your procurement process. Sample units are available upon request, providing assurance and facilitating informed decision-making before larger commitments. Trust our streamlined logistics for reliable and consistent delivery-meeting deadlines and expectations in every order.

FAQ's of Hydro Testing Pump:

Q: How does a Hydro Testing Pump function in high-pressure applications?

A: A Hydro Testing Pump operates by generating high hydraulic pressure to test the strength and integrity of pipes, tubes, or pressure vessels. The process involves filling the object with water and pressurizing it to identify leaks or weaknesses.Q: What are the main benefits of using this elite Hydro Testing Pump?

A: The key benefits include unrivaled pressure capability, durable build, energy-efficient operation, and versatility across varied industrial applications. Favorable reviews highlight its reliability in both routine testing and stringent inspection procedures.Q: When is hydrostatic testing with this pump recommended?

A: Hydrostatic testing is typically recommended during the installation, maintenance, or commissioning of new or repaired piping systems, pressure vessels, and tubes to ensure system safety and compliance with regulatory standards.Q: Where can this Hydro Testing Pump be used?

A: This top-drawer pump is versatile for use in construction, oil and gas, chemical processing, and manufacturing industries-essentially anywhere hydrostatic testing of pressurized equipment is required.Q: What is the process for ordering and receiving a sample unit?

A: To request a sample, contact our sales team. We will provide detailed information on outlay, arrange prompt freight for domestic delivery, and ensure you receive a working unit for thorough evaluation before placing larger orders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

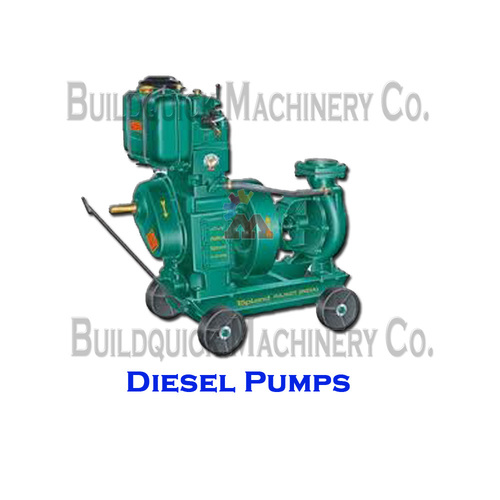

Diesel Pump

Minimum Order Quantity : 5 Pieces

Production Capacity : 1200 Liters/hour

Usage & Applications : Fuel transfer, irrigation, industrial fluid dispensing

Surface Treatment : Other, Powder Coated

Operating Type : Semi Automatic

Product Type : Other

Submersible Pump

Production Capacity : 500 Units/Month

Usage & Applications : Agricultural, Industrial, Domestic Water Supply, Irrigation, Drainage, Construction Sites

Surface Treatment : Other, Powder Coated

Operating Type : Automatic

Product Type : Other, Submersible Pump

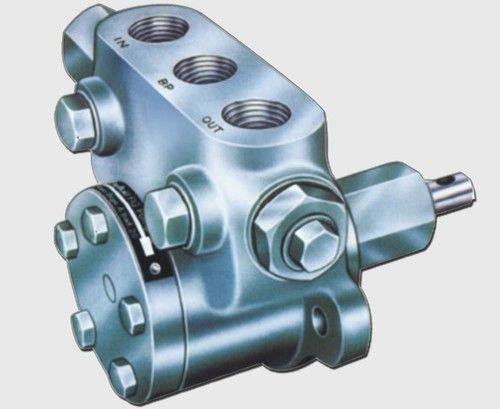

Injection Internal Gear Pump

Minimum Order Quantity : 1 Piece

Production Capacity : Up to 360 m3/hr

Usage & Applications : Oil Burners, Boilers, Hydraulic Dry Pressure Pumps, Lubrication oil, Hydraulic oil, PHF Units, Filter Bowstring, Diesel in Locomotives, Petroleum Industries, Force feed Lubrication, Pressure Regulator.

Surface Treatment : Other

Operating Type : Semi Automatic

Product Type : Other

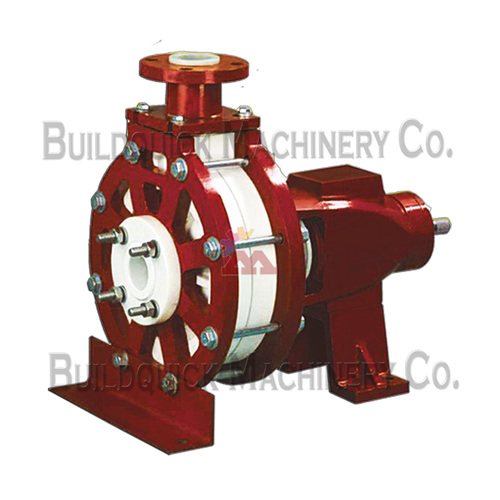

Corrosion Resistant Polypropylene Centrifugal Pump

Minimum Order Quantity : 1 Piece

Production Capacity : Up to 50 m3/hr

Usage & Applications : Water Treatment Plant, Effluent Treatment Plant, Electro Planting, Pickling & Steel Rolling mills, Excellent for Transfer & Loading Unloading Like HCL,Sulphuric acid/Alkali, Caustic Liquid, Scrubbing of Corrosive Gases like Co2,So3,So2,I2,F2,Br2,CI2,Etc... For Handling Liquids in Various Industry link Textiles, Paper, Cellulose, Sugar, Steel, Food Having Temperature Range Materials, Etc... Ideal for Circulation of Pickling line & Scrubbing in Steel Plants.High Capacity Transfer Pump, Filter press for Dyes & Chemicals, Descaling, Oil & Other Fuels.

Surface Treatment : Other

Operating Type : Semi Automatic

Product Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS