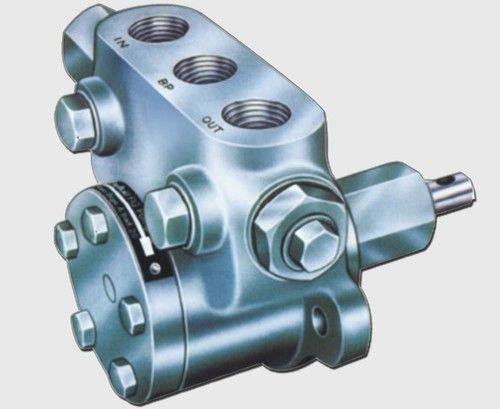

Injection Internal Gear Pump

Injection Internal Gear Pump Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Pressure

- Up to 30 kgf/cm2

- Surface Treatment

- Other

- Production Capacity

- Up to 360 m3/hr

- Usage & Applications

- Oil Burners, Boilers, Hydraulic Dry Pressure Pumps, Lubrication oil, Hydraulic oil, PHF Units, Filter Bowstring, Diesel in Locomotives, Petroleum Industries, Force feed Lubrication, Pressure Regulator.

Injection Internal Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Injection Internal Gear Pump

MP IIGFuel Injection internal Gear Pump

| Capacity | Up to 360M^3/Hr |

| Velocity of Liquid | Up to 450CST |

| Temperature | Up to 200 |

| Speed | 1440/2800 Rpm |

| Pressure | Up to 30 Kg/cm^2 |

| Direction | Rotating Clockwise [R] & Anti Clockwise [L], |

| M.O.C. | C.I. & C.S. |

Application

- Oil Burners,

- Boilers,

- Hydraulic Dry Pressure Pumps,

- Lubrication oil,

- Hydraulic oil,

- PHF Units,

- Filter Bowstring,

- Diesel in Locomotives,

- Petroleum Industries,

- Force feed Lubrication,

- Pressure Regulator.

Efficient Pressure Handling

With the ability to manage pressures up to 30 kgf/cm2, this pump ensures reliable operation in heavy-duty environments. Its internal gear design minimizes leakage and maximizes efficiency, making it a preferred choice for critical applications such as force feed lubrication and pressure regulation in industrial settings.

Versatile Applications Across Industries

The pump is suitable for varied sectors including oil burners, boilers, PHF units, and diesel transfer for locomotives. This versatility means users in petroleum industries and hydraulic systems can trust the pump for consistent fluid transfer and system integrity, improving overall workflow and productivity.

FAQ's of Injection Internal Gear Pump:

Q: How does the Injection Internal Gear Pump work in oil burners and hydraulic systems?

A: This pump utilizes an internal gear mechanism powered by electricity to deliver precise, semi-automatic fluid movement under high pressure, ensuring optimal performance in oil burners, hydraulic pressure pumps, and lubrication systems.Q: What are the key benefits of using this pump for diesel transfer in locomotives or petroleum industries?

A: It offers consistent pressure regulation, high volumetric efficiency, and reliable operation, significantly reducing downtime and maintenance while ensuring safe, continuous diesel and oil transfer in demanding locomotive and petroleum environments.Q: When should the Injection Internal Gear Pump be used over other types of pumps?

A: This pump is recommended when high pressure, semi-automatic control, and handling of lubrication or hydraulic oils are required, especially in industrial settings demanding flow rates up to 360 m3/hr.Q: Where is the pump commonly installed in industrial systems across India?

A: It is widely used in boilers, oil burners, PHF units, hydraulic dry pressure setups, filter bowstrings, and pressure regulation circuits found in petroleum refineries and locomotive service stations.Q: What is the process for installing and commissioning this pump?

A: Typically, installation involves securing the pump to the desired system, connecting electrical power, aligning the inlet and outlet for fluid transfer, and calibrating the semi-automatic controls as per operating requirements. Professional servicing is recommended for optimal setup.Q: How is the pump advantageous for force feed lubrication or pressure regulator systems?

A: Its precision internal gear mechanism ensures unwavering pressure consistency, enhancing lubrication and regulating pressure, which helps maintain machinery longevity and system dependability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

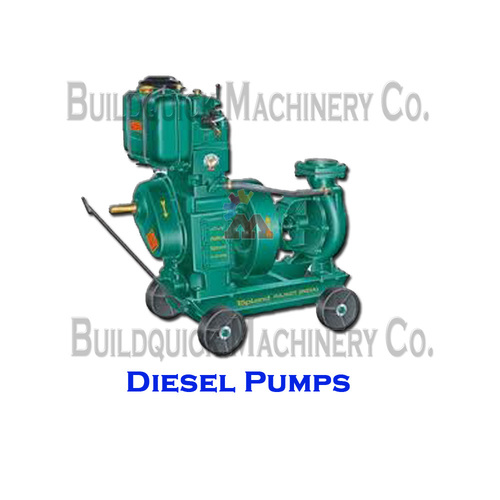

Diesel Pump

Minimum Order Quantity : 5 Pieces

Surface Treatment : Other, Powder Coated

Operating Type : Semi Automatic

Product Type : Other

Power : 5 HP

Power Source : Diesel

Horizontal centrifugal Mono-block Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Operating Type : Semi Automatic

Product Type : Other

Power : 380V415V,3Phase/200V 240V,1 Phase Volt (v)

Power Source : Electricity

MP GD Dewatering Submersible Pump

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Operating Type : Semi Automatic

Product Type : Other

Power : 415V,3Phase Volt (v)

Power Source : Electricity

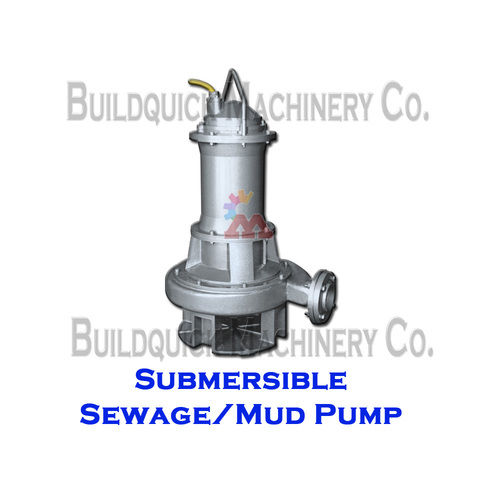

Submersible Sewage Mud Pump (MP GS HD)

Minimum Order Quantity : 1 Piece

Surface Treatment : Other

Operating Type : Semi Automatic

Product Type : Other

Power : 415V,3Phase Volt (v)

Power Source : Electricity

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS