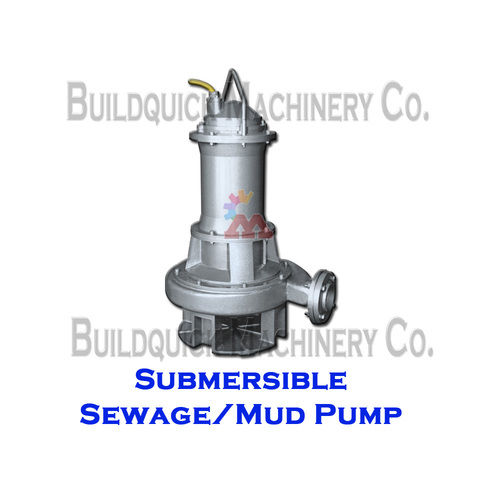

Submersible Sewage Mud Pump (MP GS HD)

Submersible Sewage Mud Pump (MP GS HD) Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 415V,3Phase Volt (v)

- Surface Treatment

- Other

- Production Capacity

- Up to 2000 m3/hr

- Usage & Applications

- Muddy Water Transfer, Effluent transfer, ETP, STP, Waste Treatment plant, Hotel, Hospital, Railway, Dairy, Power Plant, Chamical Industries, Sugar,ETC..

Submersible Sewage Mud Pump (MP GS HD) Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About Submersible Sewage Mud Pump (MP GS HD)

MP GS HD

Low speed Heavy Duty Sewage & Effluent Submersible Pump.

| Capacity | Up to 2000M3/Hr |

| Head | Up to 70Mtr |

| Temperature | 45 degree Celsius |

| Hp | 2 to 200 |

| Speed | 960 to 1440 Rpm |

| Delivery size | 50 mm to 200 mm |

| Solid size | 125 mm |

| Connection | Dol,Star Delta,ATS |

| Voltage & Phase | 415 V,3 Phase |

| Insulation/Protection | F' Class/'H"Class-IP 68 |

| Cable | PVC insulation Double seated copper Conductor Flexible cable |

| Mechanical Seal | Bi-Directional Twin Mechanical Seal with various face Combination looking to the application |

| M.O.C. | C.I., C.S.,S.S. |

Optional Part

- Impeller,

- Casing,

- Wear Plate with various M.O.C.,

- Bronze,

- CF8,

- CF8M,

- CD4MCU,ETC..

Application

- Muddy Water Transfer,

- Effluent transfer,

- ETP,

- STP,

- Waste Treatment plant, Hotel,

- Hospital,

- Railway,

- Dairy,

- Power Plant,

- Chamical Industries,

- Sugar,ETC..

High-Capacity Sewage and Mud Handling

This submersible mud pump is specifically built to transfer large volumes of contaminated, muddy water and effluents. Its heavy-duty construction allows seamless operation even with viscous liquids and fibrous materials, making it perfect for emergencies and continuous operations in harsh environments.

Versatile Applications Across Industries

From wastewater treatment plants to hotels, hospitals, and industrial complexes, this pump is a valuable asset for any facility that needs efficient effluent transfer and mud pumping. Its adaptability across sectors marks it as a versatile utility pump that meets a diverse set of operational challenges.

Reliable, Industrial-Grade Performance

Designed for long-term durability and energy efficiency, the pump uses a 3-phase electricity source for consistent performance. Semi-automatic controls ensure simplified operation and reduced maintenance efforts, contributing to lower downtime and increased productivity on-site.

FAQ's of Submersible Sewage Mud Pump (MP GS HD):

Q: How does the Submersible Sewage Mud Pump (MP GS HD) operate?

A: This pump operates semi-automatically, utilizing a 415V, 3-phase power supply. When submerged in muddy or effluent-rich water, it efficiently draws the liquid through its inlet, processes it, and discharges it for further treatment or safe disposal, making it ideal for continuous or emergency applications.Q: What are the main uses and applications of this mud pump?

A: The pump is designed for transferring muddy water and effluents in environments such as ETPs, STPs, waste treatment plants, hotels, hospitals, railways, dairies, power plants, and chemical or sugar industries, making it suitable for diverse industrial and commercial settings.Q: When should I consider using a submersible mud pump in my facility?

A: You should consider using this pump when handling large volumes of waste, contaminated, or muddy water-especially where manual or standard pumps are insufficient. It's particularly useful during flooding, tank cleaning, or continuous effluent management processes.Q: Where can the Submersible Sewage Mud Pump (MP GS HD) be installed?

A: It can be installed wherever efficient liquid transfer is required-underground tanks, sumps, effluent pits, treatment plant basins, or any location with accumulated waste or mud-heavy water. Due to its submersible design, the pump can function directly within the liquid medium.Q: What process does the mud pump use to handle sludge and waste?

A: The pump draws in the sludge through its intake, where a robust impeller mechanism disperses the solid-laden mixture, allowing uninterrupted flow through to the discharge. Its construction prevents clogging and ensures effortless passage of thick or fibrous waste.Q: How does using this pump benefit my facility's operation?

A: This pump streamlines liquid waste management by increasing transfer capacity, reducing manual effort, minimizing downtime, and enhancing overall efficiency. It can handle large volumes swiftly, ensuring your facility meets environmental and safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

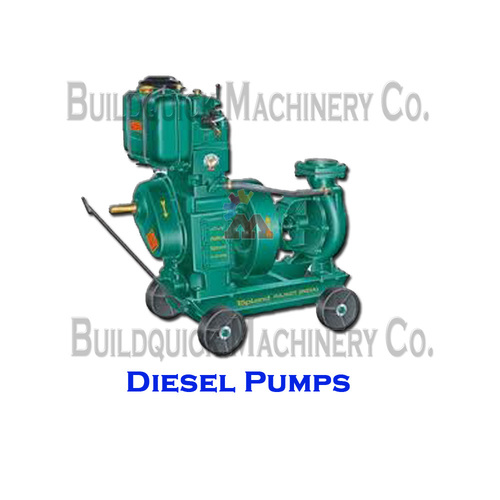

Diesel Pump

Minimum Order Quantity : 5 Pieces

Pressure : 180 bar

Usage & Applications : Fuel transfer, irrigation, industrial fluid dispensing

Production Capacity : 1200 Liters/hour

Product Type : Other

Surface Treatment : Other, Powder Coated

Submersible Pump

Pressure : Up to 15 Bar

Usage & Applications : Agricultural, Industrial, Domestic Water Supply, Irrigation, Drainage, Construction Sites

Production Capacity : 500 Units/Month

Product Type : Other, Submersible Pump

Surface Treatment : Other, Powder Coated

Horizontal centrifugal Mono-block Pump

Minimum Order Quantity : 1 Piece

Pressure : Up to 4.5 kgf/cm2

Usage & Applications : Power Plant, Fire Fighting, Gardening & Irrigation, Agriculture, Farms, Civil Application, Industries for Clean Water Handling, Cooling Tower, Water Supply for Domestic use in Apartment, Building Commercial Complex, Hotel, Swimming Pool, Automobile Services Station, Hospital, Clubs,Etc...

Production Capacity : Up to 120 m3/hr

Product Type : Other

Surface Treatment : Other

Vertical Long Shaft Sump Pumps

Minimum Order Quantity : 1 Piece

Pressure : Up to 6 kgf/cm2

Usage & Applications : The Sump Pump is Suitable for Handling Thin, Clear or Slightly Contaminated Liquid, Such as Water, Cooling Water Effluent, Cleaning Product, Chemical & Hydrocarbons, Sulphuric acid application, Acid transfer, Aquariums, Chemical processing, Etc....

Production Capacity : Up to 325 m3/hr

Product Type : Other

Surface Treatment : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS