MP GD Dewatering Submersible Pump

MP GD Dewatering Submersible Pump Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 415V,3Phase Volt (v)

- Surface Treatment

- Other

- Production Capacity

- Up to 132 m3/hr

- Usage & Applications

- "Muddy Water Transfer, Effluent transfer, ETP,STP, Waste Treatment plant, Hotel, Hospital, Railway, Dairy, Power Plant, Chemical Industries, Sugar, Steel,Cement, Food Beverages,Civil Construction- Deeatering Foundations, Trenches & Pits,Punlic utilities,ETC.."

MP GD Dewatering Submersible Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About MP GD Dewatering Submersible Pump

| MP GD Dewatering Submersible Pump. | ||

| 1 | Capacity | Up to 132M^3/Hr |

| 2 | Head | Up to 50Mtr |

| 3 | Temperature | 70 |

| 4 | Hp | Up to 50 |

| 5 | Speed | Up to 2900 Rpm |

| 6 | Delivery size | 1.5mm to 200mm |

| 7 | Solid size | 35mm |

| 8 | Connection | Dol |

| 9 | Voltage & Phase | 415V,3Phase |

| 10 | Insulation/Protection | F' Class/'H"Class-IP 68 |

| 11 | Cable | PVC insulation Double seated copper Conductor Flexible cable |

| 12 | Mechanical Seal | Double Mechanical seals(Tungsten Carbide Vs Tungsten Carbide) |

| 13 | M.O.C. | Alluminium Alloy LM-04/ Stainless steel-304 |

| 14 |

|

|

Versatile Dewatering Performance

Designed to handle challenging environments, the MP GD Dewatering Submersible Pump efficiently transfers muddy water and effluent, supporting processes in industries like power plants, chemical facilities, civil construction, and public utilities. Its robust build and semi-automatic operation ensure consistent performance and high reliability, even in demanding conditions.

Efficient and Reliable Operation

Operating on a 415V three-phase power supply, this pump delivers a production capacity of up to 132 m3/hr, making it suitable for extensive dewatering requirements. The semi-automatic functionality streamlines the pumping process, minimizing manual intervention and maximizing operational uptime.

FAQ's of MP GD Dewatering Submersible Pump:

Q: How does the MP GD Dewatering Submersible Pump operate for muddy water transfer?

A: The pump uses semi-automatic controls to efficiently extract and move muddy water, effluent, or wastewater through its submersible design, ensuring uninterrupted flow and effective dewatering in applications like trenches, pits, and foundations.Q: What are the key industries where this pump is used?

A: This pump is widely utilized in sectors such as waste treatment plants, hospitals, hotels, railways, dairies, chemical and food processing industries, steel and cement factories, and civil construction projects across India.Q: When is the MP GD Dewatering Submersible Pump most beneficial?

A: It is most advantageous during conditions that require rapid removal of large volumes of water or effluent, such as heavy rains, flooding, or routine water management in industrial and municipal settings.Q: Where can I install this pump for optimal performance?

A: The pump is suitable for installation in muddy areas, effluent pits, trenches, dewatering foundations, ETPs, STPs, and other locations needing efficient water transfer. It's built for submerged operation in demanding environments.Q: What is the setup process for the semi-automatic operation of the pump?

A: Installation involves positioning the pump in a submerged location, connecting it to a 415V 3-phase power supply, and configuring the semi-automatic controls to initiate dewatering as required. Professional installation ensures safe and optimal functioning.Q: How does using this pump benefit my industry or utility?

A: By deploying this pump, you ensure reliable and rapid dewatering, reduce downtime, lower maintenance costs due to its sturdy construction, and maintain a safer working environment with efficient water management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

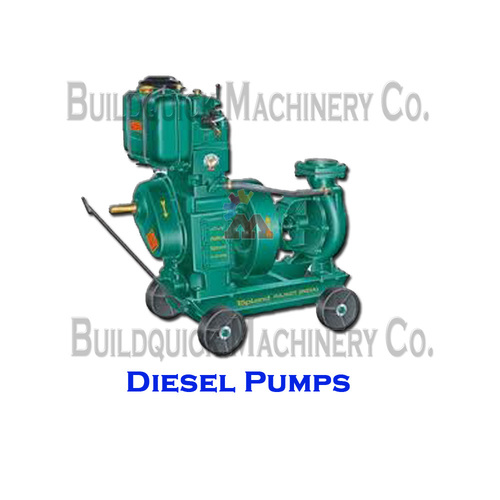

Diesel Pump

Minimum Order Quantity : 5 Pieces

Usage & Applications : Fuel transfer, irrigation, industrial fluid dispensing

Pressure : 180 bar

Power Source : Diesel

Operating Type : Semi Automatic

Product Type : Other

Submersible Pump

Usage & Applications : Agricultural, Industrial, Domestic Water Supply, Irrigation, Drainage, Construction Sites

Pressure : Up to 15 Bar

Power Source : Other, Electric

Operating Type : Automatic

Product Type : Other, Submersible Pump

Mud Pump

Usage & Applications : Drilling mud circulation in oilfield and mining

Pressure : 7 MPa

Power Source : Other, Electric

Operating Type : Automatic

Product Type : Other, Reciprocating Positive Displacement Pump

Vertical Long Shaft Sump Pumps

Minimum Order Quantity : 1 Piece

Usage & Applications : The Sump Pump is Suitable for Handling Thin, Clear or Slightly Contaminated Liquid, Such as Water, Cooling Water Effluent, Cleaning Product, Chemical & Hydrocarbons, Sulphuric acid application, Acid transfer, Aquariums, Chemical processing, Etc....

Pressure : Up to 6 kgf/cm2

Power Source : Electricity

Operating Type : Semi Automatic

Product Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS