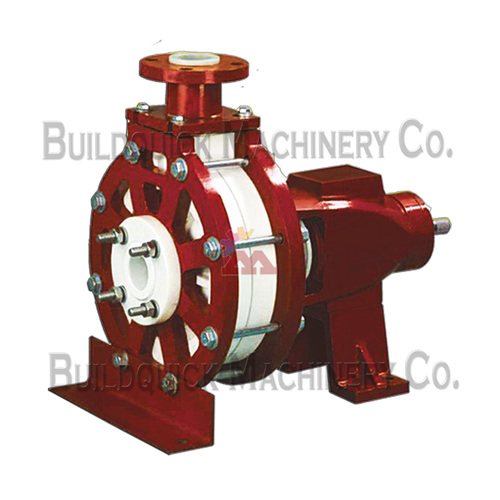

Centrifugal Pump MP CPP

Price 22000 INR/ Piece

Centrifugal Pump MP CPP Specification

- Product Type

- Other

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Pressure

- Up to 15 kgf/cm2

- Surface Treatment

- Other

- Production Capacity

- Up to 2200 m3/hr

- Usage & Applications

- Hot & Cold Water Circulation, Cooling water Circulation, Drip Irrigation, Water Supply & Building Services, Thermic Fluid, Jet Drying, Volatile Fluids, Condensate Handling, Fire Fighting system, Environmental,Engineering,Marin, Refrigeration & Cooling Tower Installation Etc.. Chemical, Sugar, Petrochemicals, Refineries Paper, Laminates Industries, Rubber Industries, Handing of Hydrocarbons, Organic & Inorganic chemical, Condensate DM Water, Food Industries, Textile Industries, Power Station & Industries Such as Pulp, Fertilizer,ETC... Corrosive and Abrasive Process Chemical Like Acid, Alkali, Solvent, Slurry, Hydrocarbons, Ammonia, Crystallization Liquid, Chemical Fluent,ETC...

Centrifugal Pump MP CPP Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID)

- Main Domestic Market

- All India

About Centrifugal Pump MP CPP

| MP CPP Single Stage,Eng Suction Back Pull Out type Centrifugal Pump | ||

| 1 | Capacity | Up to 2200M^3/Hr |

| 2 | Head | Up to 150Mtr |

| 3 | Temperature | 350 |

| 4 | Speed | Up to 3500Rpm |

| 5 | Discharge size | 25mm to 300mm |

| 6 | Pressure | Up to 15 Kg/cm 2 |

| 7 | M.O.C. | C.I., C.S.,S.S-304/304L,316/316L,Bronze,Alloy-20,CD4MCU Hast Alloy B&C,etc.. |

| 8 | Application |

|

Engineered for Versatility and Performance

The MP CPP centrifugal pump delivers reliable performance across demanding industrial settings. Whether it's managing hot or cold fluids, circulating cooling water, or transferring volatile and abrasive chemicals, its design ensures operational flexibility and longevity. Its high production capacity and pressure tolerance make it the preferred solution for sectors ranging from fire safety systems to chemical processing.

Suited for Challenging Industrial Applications

Built to endure the rigors of continuous operation, the MP CPP pump is trusted in diverse environments: from environmental engineering to pulp and textile processing. Its robust construction allows handling of corrosive acids, alkalis, slurry, and even thermic fluids. Users benefit from seamless integration in water supply systems, cooling towers, and specialized process lines across a wide spectrum of industries.

FAQ's of Centrifugal Pump MP CPP:

Q: How does the Centrifugal Pump MP CPP handle corrosive and abrasive fluids?

A: The pump is constructed with materials designed to resist wear and corrosion, making it highly suitable for transferring acids, alkalis, solvents, slurry, and other challenging process chemicals. Specialized sealing and lining options further enhance its capability in aggressive environments.Q: What are the primary industrial applications for the MP CPP pump?

A: This pump supports a vast range of uses such as hot and cold water circulation, condensate handling, fire fighting systems, cooling tower installations, as well as chemical and petrochemical fluid transfer in manufacturing sectors like sugar, textiles, paper, and power stations.Q: When is it beneficial to use the MP CPP centrifugal pump?

A: It is most beneficial when industries require dependable, high-capacity and high-pressure fluid transfer solutions, especially where corrosive, abrasive or temperature-sensitive fluids are present or where continuous semi-automatic operation is essential.Q: Where can the MP CPP pump be installed?

A: Suitable for both indoor and outdoor installations, the MP CPP pump finds use in industrial plants, water treatment facilities, fire safety stations, chemical processing units, and building service infrastructures across India.Q: What are the operational benefits of using this centrifugal pump?

A: Customers benefit from high efficiency, extended operational lifespan, minimal downtime, and versatile handling of a broad spectrum of fluids, ensuring cost-effectiveness and reliability in complex industrial processes.Q: How is maintenance managed for this pump model?

A: Routine checks and preventive maintenance are straightforward due to the pump's semi-automatic design and accessible components. Service support and spare parts are readily available through the distributor, manufacturer, and supplier network across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 11 PUMPS Category

Submersible Pump

Usage & Applications : Agricultural, Industrial, Domestic Water Supply, Irrigation, Drainage, Construction Sites

Technology : Other, Centrifugal Pump Technology

Surface Treatment : Other, Powder Coated

Operating Type : Automatic

Production Capacity : 500 Units/Month

Mud Pump

Usage & Applications : Drilling mud circulation in oilfield and mining

Technology : Other, Threecylinder Singleacting

Surface Treatment : Other, Paint Coated

Operating Type : Automatic

Production Capacity : 45 m/h

Corrosion Resistant Polypropylene Centrifugal Pump

Minimum Order Quantity : 1 Piece

Usage & Applications : Water Treatment Plant, Effluent Treatment Plant, Electro Planting, Pickling & Steel Rolling mills, Excellent for Transfer & Loading Unloading Like HCL,Sulphuric acid/Alkali, Caustic Liquid, Scrubbing of Corrosive Gases like Co2,So3,So2,I2,F2,Br2,CI2,Etc... For Handling Liquids in Various Industry link Textiles, Paper, Cellulose, Sugar, Steel, Food Having Temperature Range Materials, Etc... Ideal for Circulation of Pickling line & Scrubbing in Steel Plants.High Capacity Transfer Pump, Filter press for Dyes & Chemicals, Descaling, Oil & Other Fuels.

Technology : Other

Surface Treatment : Other

Operating Type : Semi Automatic

Production Capacity : Up to 50 m3/hr

SS Centrifugal Pump

Minimum Order Quantity : 1 Piece

Usage & Applications : Milk, Cream, Butter milk, Condensed Milk, Fruit Juice, Sugar Syrup, Vitamin Solution, Beer,Wine, Vegetable, Oil, Mineral Oil, Lubricating Oil, Alkaline Solution, Acids Fine Chemicals, Colour Dyes & Pigments, R.O. Water, DM Water & Pure Water, Dairy Industries, Pharmaceutical Industries, Food Industries, Textile, Paper & Cement Industries. Mono/Bare Pumps are available. Bare Pump are also Available with flame proof

Technology : Other

Surface Treatment : Other

Operating Type : Semi Automatic

Production Capacity : Up to 90 m3/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS