ROUGHNESS COMPARATOR

Price 1 INR/ Piece

ROUGHNESS COMPARATOR Specification

- Features

- Portable, Durable, Easy to use, Reference master

- Automation Grade

- Manual

- Measuring Range

- Ra 0.05 - 3.2 m

- Resolution

- Not applicable (visual/tactile reference)

- Max Height

- Approx. 10 mm

- Mounting Type

- Portable, handheld

- Frequency

- Unlimited (manual usage)

- Hardness

- Standard steel or equivalent

- Test Range

- Ra 0.05 to 3.2 m (microns)

- Number of Specimens

- 12 specimen surfaces

- Display Type

- No display

- Application

- Industrial

- Accuracy

- Surface finish value reference as per standard

- Humidity

- 5% to 90% RH (non-condensing)

- Specimen Size

- Approx. 30 x 50 mm each specimen

- Temperature

- 0C to 50C (operating)

- Equipment Type

- Roughness Comparator

- Response Time

- Immediate (visual/tactile)

- Usage

- Surface roughness comparison

- Capacity

- 12 Comparison Surfaces

- Machine Weight

- Approx. 200 g

- Test Speed

- Manual operation

- Test Width

- Standard 25 mm

- Control Mode

- Manual

- Product Code

- RC-32

- Surface Comparison Types

- Various machining processes

- Finish Patterns Available

- Turned, Milled, Ground, Lapped

- Standard Complied

- ISO/JIS/ANSI standards

- Packaging

- Plastic or wooden box

- Material of Specimens

- High-grade steel

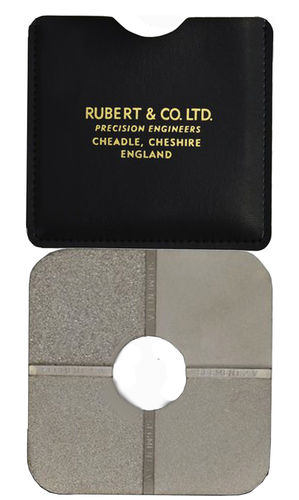

About ROUGHNESS COMPARATOR

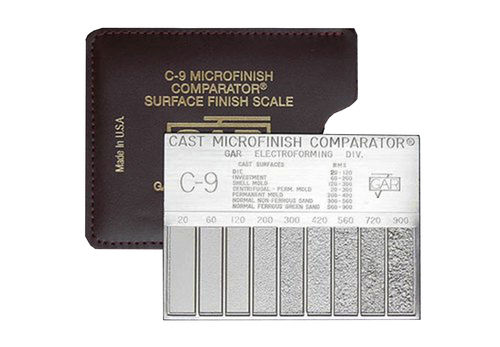

These two comparators are specially designed to check the roughness of steel surfaces which have been blast cleaned to cleanliness grades SA 2.5 and SA 3 in preparation for painting.

They conform to ISO 8503.

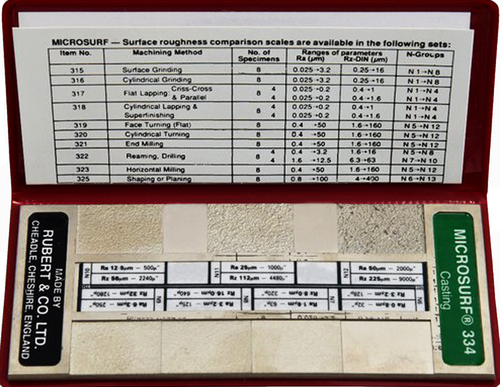

Comprehensive Surface Comparison

The roughness comparator features 12 specimen surfaces representing a variety of machining finishes such as turned, milled, ground, and lapped. These provide a practical reference standard, adhering to major ISO, JIS, and ANSI specifications. Each specimen is crafted from high-grade steel for accuracy and longevity, making it suitable for diverse applications in quality control or manufacturing environments.

Portable and User-Friendly Design

With its lightweight construction (approx. 200 g) and handheld, portable form factor, the comparator is easy to carry and operate directly at the inspection site. Packaged in either a plastic or wooden box, it stays protected while remaining convenient for storage and transport. Its manual operation requires no electricity, digital displays, or maintenance, offering dependable performance at any time.

Immediate and Reliable Assessment

Engineered for manual use, the RC-32 enables immediate surface finish comparison, utilizing visual and tactile reference rather than electronic measurement. Its test range spans Ra 0.05 to 3.2 m, covering the most common industrial roughness grades. This ensures rapid evaluation and increased efficiency for inspectors evaluating parts, components, or production processes.

FAQ's of ROUGHNESS COMPARATOR:

Q: How do I use the ROUGHNESS COMPARATOR RC-32 to compare surface finishes?

A: To use the RC-32, select one of its 12 specimen surfaces that closely matches your workpiece finish type (turned, milled, ground, or lapped). Place your sample adjacent to the relevant specimen and compare the tactile or visual texture to estimate the roughness value (Ra) as per the provided reference standard.Q: What is the main benefit of using this roughness comparator in industrial settings?

A: The primary benefit is quick and reliable surface finish assessment without the need for electronic gauges. It allows operators to reference standardized surface textures immediately, ensuring quality control while saving time during inspections.Q: When is it appropriate to use this comparator rather than digital roughness testers?

A: This comparator is ideal for routine inspections, training, or situations where portability and speed are crucial. It is especially valuable when only a quick reference is needed rather than precise digital measurement, or where electronic equipment is impractical.Q: What materials and surface types can I assess with the RC-32?

A: The comparator is crafted from high-grade steel and covers 12 comparison types, including turned, milled, ground, and lapped surfaces, compliant with ISO, JIS, and ANSI standards. It is suitable for a wide range of metal and manufactured parts.Q: Where should the comparator be stored when not in use?

A: For best equipment preservation, store the comparator in its provided packaging-either a plastic or wooden box-in a clean, dry environment within the recommended humidity and temperature range (0C to 50C, 5% to 90% RH non-condensing).Q: How accurate are the roughness values obtained with this device?

A: The RC-32 provides surface finish values as a reference according to established standards, ensuring consistent and repeatable comparisons. Accuracy relies on the quality of reference specimens and user proficiency with visual and tactile evaluations.Q: Is there any maintenance required for this manual comparator?

A: Routine wiping to remove dust and fingerprints is sufficient for maintenance. No calibration or electronic servicing is necessary due to its purely mechanical, reference-based operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 13 PRECISION & TESTING INSTRUMENTS Category

SURFACE ROUGHNESS TESTER

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Handheld

Measuring Range : 0.05 10.00 m

Features : Portable, Rechargeable, Easy Calibration

Usage : Quality Control

ROUGHNESS COMPARATOR

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Handheld

Measuring Range : 0.05 m to 3.2 m Ra

Features : High Precision, Portable, Multiple Reference Specimens

Usage : Surface Roughness Assessment

Roughness Comparator

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Mounting Type : Handheld

Measuring Range : 0.025 to 1.6 m Ra

Features : Portable, easy to use, reference for multiple finishes

Usage : Surface roughness comparison

Holiday Detector

Mounting Type : Handheld

Measuring Range : 0 to 30 kV (according to model specification)

Features : Lightweight, Portable, Adjustable Voltage, AudioVisual Alarm

Usage : For detection of holidays (defects) in coatings on pipelines, tanks, etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS