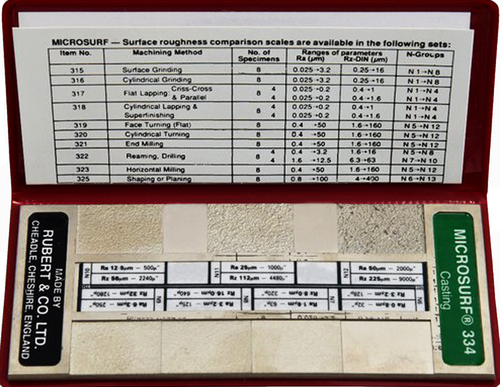

ROUGHNESS COMPARATOR

Price 1 INR/ Piece

ROUGHNESS COMPARATOR Specification

- Temperature

- 10C - 40C

- Display Type

- Visual / Comparator

- Specimen Size

- 25 mm x 9 mm each

- Automation Grade

- Manual

- Hardness

- HRC 58 2 (Steel Specimens)

- Mounting Type

- Handheld

- Number of Specimens

- 12

- Power Supply

- No Power Required

- Max Height

- 10 mm

- Equipment Type

- Roughness Comparator

- Features

- High Precision, Portable, Multiple Reference Specimens

- Humidity

- Operating 20% - 80% RH

- Measuring Range

- 0.05 m to 3.2 m Ra

- Response Time

- Instantaneous

- Application

- Industrial

- Test Range

- 0.05 m to 3.2 m Ra

- Accuracy

- 0.01 m

- Resolution

- 0.01 m

- Usage

- Surface Roughness Assessment

- Capacity

- 12 Specimens

- Machine Weight

- Approx. 0.2 kg

- Test Speed

- Manual Movement

- Test Width

- Standard Width - 25 mm

- Test Stroke

- 50 mm

- Control Mode

- Manual

- Calibration

- Factory Calibrated

- Surface Types

- Flat

- Material

- Tool Steel

- Packing Type

- Plastic Box with Foam Insert

- Model Number

- RC-12

- Finish Types

- Ground, Milled, Turned, Polished

About ROUGHNESS COMPARATOR

This is a range of light-weight comparators more suited to office and design shop use. Each set in the range is presented in a plastic wallet, with an instruction card giving full details on the roughness values of the specimens.

Comprehensive Roughness Evaluation

The RC-12 Roughness Comparator covers various finish types such as ground, milled, turned, and polished. This versatility supports a wide array of industrial surface assessments. Its standardized flat samples ensure consistent, precise comparison, making it indispensable for machinists, QC inspectors, and engineers.

Factory Calibrated and Highly Accurate

Each reference specimen is factory calibrated, guaranteeing repeatable and trustworthy results. With 0.01 m accuracy and resolution, professionals can confidently evaluate surface quality within a test range of 0.05 m to 3.2 m Ra. The device requires no calibration before use, streamlining your inspection process.

Portable, Durable, Ready-to-Use

Measuring approximately 0.2 kg and stored in a plastic box with foam insert, the RC-12 is easy to transport for field work or interdepartmental use. Its robust tool steel construction ensures long-lasting durability, while manual operation provides users with control and rapid response without any need for external power.

FAQ's of ROUGHNESS COMPARATOR:

Q: How do I use the RC-12 Roughness Comparator for surface assessment?

A: Simply select the appropriate reference specimen matching your desired finish (ground, milled, turned, or polished). Manually slide your test sample across the comparator's specimen to visually and tactilely compare surface textures. No power supply or additional tools are required.Q: What surfaces can the RC-12 measure and compare?

A: The RC-12 is designed to assess flat surface types and can be used on a variety of ferrous and non-ferrous parts, particularly those requiring high-precision roughness evaluation in industrial environments.Q: When should I use a roughness comparator like the RC-12?

A: Use the RC-12 during quality control, machine setup, or routine inspections whenever you need to verify that component surfaces meet specified roughness standards. It's especially useful for immediate, on-site assessments in production facilities.Q: Where can the RC-12 Roughness Comparator be used most effectively?

A: This tool is best suited for industrial settings such as manufacturing floors, inspection rooms, or workshops where portability and quick, visual surface comparison are essential.Q: What is the process for checking surface finish with the RC-12?

A: Place your manufactured part against the relevant reference specimen. Assess both visually and by feel to determine similarity, ensuring surface qualities align with your requirements. The process is manual and offers instant comparison results.Q: What are the key benefits of using this manual comparator?

A: The RC-12 delivers accurate, immediate surface roughness assessment without needing power. Its portability, multiple reference specimens, and durable storage case increase efficiency and convenience for quality control teams.Q: How is the RC-12 delivered or stored when not in use?

A: It is supplied in a sturdy plastic box with an internal foam insert, protecting each specimen and making the comparator easy to store or transport between work areas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 13 PRECISION & TESTING INSTRUMENTS Category

SURFACE ROUGHNESS TESTER

Usage : Quality Control

Response Time : 1 second

Application : Surface Profile Measurement

Features : Portable, Rechargeable, Easy Calibration

Mounting Type : Handheld

Display Type : LCD Digital Display

Holiday Detector

Usage : For detection of holidays (defects) in coatings on pipelines, tanks, etc.

Response Time : Instantaneous

Application : Detecting pinholes, cracks, and coating discontinuities in protective coatings

Features : Lightweight, Portable, Adjustable Voltage, AudioVisual Alarm

Mounting Type : Handheld

Display Type : Digital LED Display

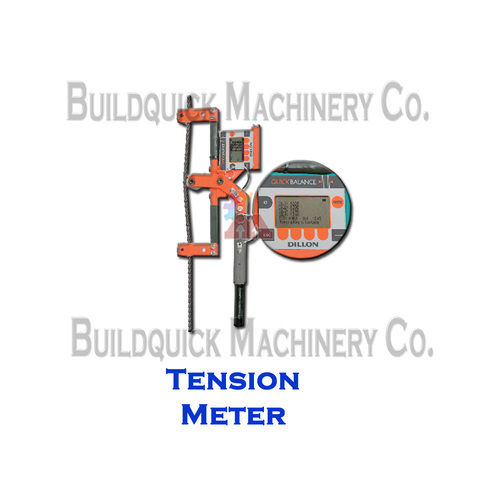

Tension Meter

Usage : Textile, Laboratory, Industrial

Response Time : Instantaneous

Application : Measuring tension of yarn, filament, wire, thread, etc.

Features : Portable, Handheld, Easy to Use

Mounting Type : Handheld

Display Type : Analog Dial

Vernier Caliper

Usage : Precision measurement in mechanical engineering and machining processes

Response Time : Realtime

Application : Measurement of external internal step and depth dimensions

Features : Durable stainless steel construction; Digital display for precise readings

Mounting Type : Handheld

Display Type : Digital

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS