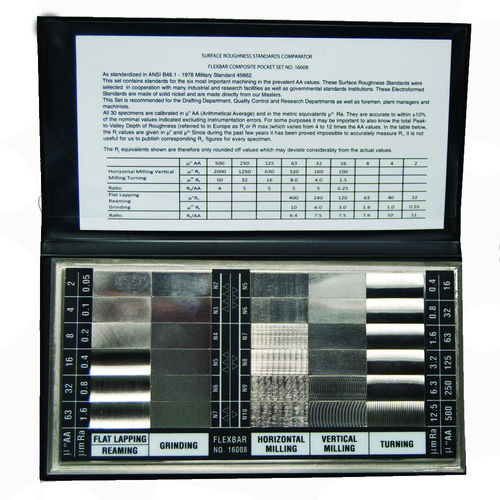

Roughness Comparator

Price 1 INR/ Piece

Roughness Comparator Specification

- Humidity

- 85%RH

- Measuring Range

- 0.025 to 1.6 m Ra

- Mounting Type

- Handheld

- Display Type

- Visual Comparator

- Response Time

- Instant

- Hardness

- Approx. 58 HRC

- Test Range

- 0.025 to 1.6 m Ra

- Application

- Industrial

- Number of Specimens

- 12 specimens

- Specimen Size

- 50 mm x 20 mm

- Accuracy

- 0.005 m on standards

- Max Height

- 20 mm

- Features

- Portable, easy to use, reference for multiple finishes

- Temperature

- 0C to 40C

- Automation Grade

- Manual

- Equipment Type

- Roughness Comparator

- Usage

- Surface roughness comparison

- Capacity

- 12 Types of Surface Finishes

- Machine Weight

- Approx. 200 g

- Test Speed

- Manual operation

- Test Width

- 10 mm

- Control Mode

- Manual

- Finish Types

- Rough to smooth

- Material

- Precision steel

- Surface Preparation Standards

- CNC Lathe, Grinding, Milling, Reaming

- Packing

- Wooden case

- Certified Standard

- DIN ISO 1302

- Calibration

- Factory calibrated

About Roughness Comparator

Extra Features and Other Applications

The Roughness Comparator stands out with its superior portability and ergonomic, handheld mounting. Its instant visual display makes it remarkably easy to use, and the 12-specimen capacity offers a comprehensive reference for varied industrial finishes. Additional features include factory calibration, hard-wearing construction, and gilt-edged accuracy. Beyond machining, it's ideal for quality control, maintenance, and process validation in manufacturing, engineering, and laboratory environments.

Domestic Market, Certifications, and Supply Ability

Dispatched promptly across the main domestic market, the Roughness Comparator comes with certified standards, including DIN ISO 1302 compliance. Supply ability is robust, with ready availability from authorized distributors and manufacturers. Every unit is delivered securely in a wooden case at a listed price, ensuring complete calibration and certification. Fast delivery and reliable service ensure that industrial clients nationwide receive top-tier equipment consistently.

FAQ's of Roughness Comparator:

Q: How do I use the Roughness Comparator for surface comparison?

A: Simply select an appropriate specimen and visually compare the target surface against the reference, following manual operation guidelines for accurate assessment.Q: What materials and finish types does the comparator support?

A: It is crafted from precision steel and supports finishes from rough to smooth, covering CNC Lathe, Grinding, Milling, and Reaming standards.Q: Where is the Roughness Comparator supplied and serviced in India?

A: The comparator is distributed, manufactured, serviced, and supplied by authorized partners across India, with delivery to all major industrial regions.Q: What are the benefits of using a gilt-edged, factory calibrated comparator?

A: Benefits include high fidelity surface finish evaluation, preeminent accuracy (0.005 m), instant results, and confidence in certified calibration standards.Q: When will my Roughness Comparator order be dispatched?

A: Orders are typically dispatched promptly upon confirmation, with delivery timelines based on destination and distributor supply capabilities.Q: What is the process for calibration and certification?

A: Calibration is performed at the factory according to DIN ISO 1302 standards. Each unit is certified, checked for accuracy, and securely packed for delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 13 PRECISION & TESTING INSTRUMENTS Category

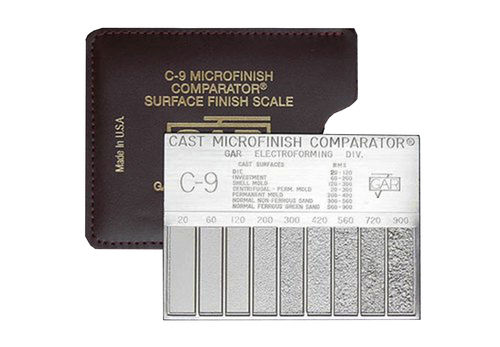

ROUGHNESS COMPARATOR

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Visual/Comparative

Application : Industrial

Usage : Surface finish comparison for quality control

Measuring Range : 0.025 m to 6.3 m (Ra)

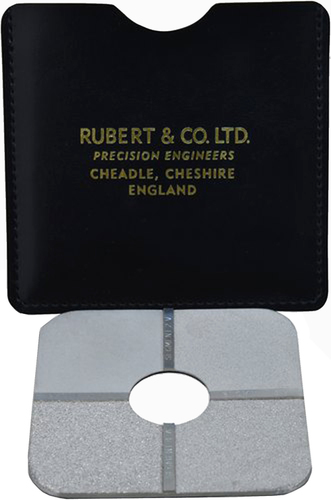

ROUGHNESS COMPARATOR

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Manual

Application : Industrial

Usage : Surface roughness reference/comparison

Measuring Range : Ra 0.025 6.3 m (varies with set)

Holiday Detector

Control Mode : Manual

Application : Detecting pinholes, cracks, and coating discontinuities in protective coatings

Usage : For detection of holidays (defects) in coatings on pipelines, tanks, etc.

Measuring Range : 0 to 30 kV (according to model specification)

Weld Inspection Kit

Control Mode : Manual operation

Application : Weld quality inspection

Usage : For inspecting weld seams and ensuring quality

Measuring Range : Varies based on tools (~0100mm for some gauges)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS