ROUGHNESS COMPARATOR

Price 1 INR/ Piece

ROUGHNESS COMPARATOR Specification

- Test Range

- Ra 0.025 - 6.3 m

- Humidity

- Suitable for indoor laboratory conditions

- Application

- Industrial

- Response Time

- Immediate

- Mounting Type

- Handheld

- Display Type

- Physical surface blocks/plates

- Hardness

- Hardened steel/aluminum sample strips

- Temperature

- Ambient (10C to 40C)

- Accuracy

- Visual/matching comparator (relative, no gauge)

- Power Supply

- Not required (mechanical device)

- Features

- Multiple surface finish standards, pocket-sized case

- Automation Grade

- Manual

- Resolution

- Limited by comparator increments

- Number of Specimens

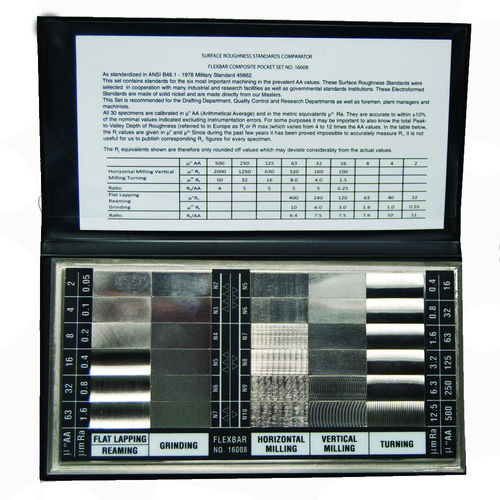

- 12 to 30 specimens (depending on set)

- Equipment Type

- Roughness Comparator

- Specimen Size

- Approx. 25 x 75 mm per strip

- Measuring Range

- Ra 0.025 - 6.3 m (varies with set)

- Max Height

- Approx. 10 mm

- Usage

- Surface roughness reference/comparison

- Machine Weight

- Lightweight (Pocket-friendly, ~200g)

- Test Speed

- N/A (Manual comparison)

- Test Width

- Up to 63 mm

- Control Mode

- Manual

- Material Type

- Stainless steel/Aluminum (corrosion-resistant)

- Case Type

- Protective plastic or leather case

- Finish Types Included

- Ground, milled, planed, turned, shaped, bored, reamed, lapped, honed

- Identification Marking

- Laser-marked surface values and procedure

About ROUGHNESS COMPARATOR

This set consists of 30 comparison specimens, covering six of the most commonly-used machining methods: 6 cylindrically turned, 6 end-milled, 6 horizontally milled, 6 surface-ground, 3 lapped, 3 reamed/drilled..25 LtrA

Corrosion-Resistant Durability

Manufactured from robust stainless steel or aluminum, these comparators resist corrosion and withstand industrial or laboratory use. The precision-machined sample strips maintain their integrity, providing reliable performance for long-term surface roughness assessment.

Wide Range of Surface Finishes

Each set features between 12 to 30 specimens, covering finishes from ground to honed. This diversity allows technicians to assess and match a variety of machining processes, making this tool adaptable to multiple applications in quality control and machining validation.

Portable and User-Friendly

Weighing roughly 200 grams and packaged in a protective case, the comparator is easy to carry and use in the field, workshop, or laboratory. Its mechanical, manual operation means no need for power or extra calibration-just select, compare, and reference instantly.

FAQ's of ROUGHNESS COMPARATOR:

Q: How do I use a roughness comparator for surface assessment?

A: Hold the desired comparator specimen next to the machined workpiece and visually or tactilely compare the surface textures. Match the finish closest to your sample to estimate the Ra value.Q: What materials are the roughness comparators made of?

A: These comparators are made from corrosion-resistant stainless steel or aluminum, making them suitable for demanding industrial or laboratory environments.Q: When should I use a roughness comparator?

A: Use a roughness comparator whenever you need a quick, visual reference for verifying or comparing the surface finish of machined parts, such as during manufacturing, inspection, or quality control processes.Q: Where can the roughness comparator be used effectively?

A: It's designed for indoor laboratory or workshop settings and is suitable for environments with ambient temperatures (10C-40C) and controlled humidity.Q: What is the process for identifying the correct surface finish using this tool?

A: Select a comparator strip with the desired process (e.g., milled, turned) and Ra value, and compare it directly against your workpiece to quickly determine the finish quality.Q: What are the benefits of using a physical roughness comparator over a digital gauge?

A: Physical comparators provide immediate, power-free visual assessment, require no calibration or batteries, and are highly portable-making them ideal for field or workshop use in environments where digital instruments might be impractical.Q: Who can supply or provide support for roughness comparators in India?

A: As distributors, manufacturers, service providers, and suppliers in India carry these roughness comparator sets, you can source them locally for prompt delivery and support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 13 PRECISION & TESTING INSTRUMENTS Category

SURFACE ROUGHNESS TESTER

Control Mode : Automatic

Usage : Quality Control

Application : Surface Profile Measurement

Features : Portable, Rechargeable, Easy Calibration

Measuring Range : 0.05 10.00 m

Power Supply : Lithiumion battery

DFT Meter

Control Mode : Manual & Automatic

Usage : Paint & coating thickness measurement

Application : Ferrous (Fe) and NonFerrous (NFe) metal coating thickness measurement

Features : Automatic recognition of substrate (Fe/NFe), battery indicator, hold function

Measuring Range : 01250um

Power Supply : 9V battery (included)

Clamp Meter

Control Mode : Manual

Usage : Electrical Testing

Application : Measuring AC voltage, current, continuity, resistance

Features : Data Hold, Max Value Hold, Backlight, Auto Power Off

Measuring Range : AC Voltage: 0600V, AC Current: 0400A, Resistance: 020M

Power Supply : 2 x 1.5V AAA Batteries

Ultrasonic Thickness Gauge

Control Mode : Automatic

Usage : Measures material thickness

Application : Thickness measurement

Features : Portable Easy to use

Measuring Range : 1.0 mm to 300 mm (depends on material)

Power Supply : Battery

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS