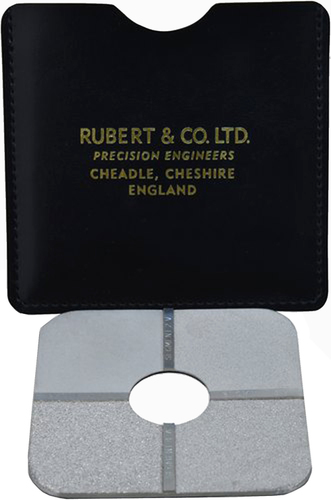

ROUGHNESS COMPARATOR

Price 1 INR/ Piece

ROUGHNESS COMPARATOR Specification

- Mounting Type

- Handheld, portable

- Specimen Size

- 25 mm 6 mm per standard

- Operating Voltage

- None (manual device)

- Interface Type

- None (manual device)

- Display Type

- Physical reference strips

- Accuracy

- According to EN/ISO 2632 (standard specific)

- Max Height

- 6 mm

- Test Range

- Ra 0.025 6.3 m

- Application

- Industrial

- Automation Grade

- Manual

- Measuring Range

- 0.025 m to 6.3 m (Ra)

- Humidity

- 0-90% RH (environmental tolerance)

- Resolution

- Varies by comparator standard

- Number of Specimens

- 12 (different surface roughness standards)

- Response Time

- Immediate (manual visual check)

- Features

- Quick surface comparison, durable metal body, easy to use

- Equipment Type

- Roughness Comparator

- Power Supply

- None (Manual device)

- Temperature

- 0C to 50C (operational ambient)

- Hardness

- Base material typically steel

- Usage

- Surface finish comparison for quality control

- Machine Weight

- 170 g

- Test Speed

- Manual

- Test Width

- 25 mm

- Control Mode

- Visual/Comparative

- Material

- Stainless Steel (comparator body)

- Dimensions

- 100 mm x 60 mm x 8 mm (approximate, including case)

- Pack Type

- Protective case included

- Finish Type

- Machined reference surfaces

- Comparator Set Types

- Includes Turning, Milling, Grinding finish standards

About ROUGHNESS COMPARATOR

These two comparators are specially designed to check the roughness of steel surfaces which have been blast cleaned to cleanliness grades SA 2.5 and SA 3 in preparation for painting.

They conform to ISO 8503.

Versatile Surface Finish Comparator

This device is engineered to provide instant, comparative surface roughness checks across a variety of machining processes, including turning, milling, and grinding. Its sturdy stainless steel construction ensures durability in challenging industrial environments. With twelve precisely machined reference surfaces, users can consistently assess and verify finish standards, making it ideal for both in-house quality assurance and external inspections.

Portable and Easy to Use

Weighing only 170 grams and supplied in a compact protective case, this handheld roughness comparator is designed for portability and straightforward operation. Its manual, visual control mode means it requires no power supply or data interface, and results are obtained instantaneously. The comparator is well-suited for various environments, thanks to its wide temperature and humidity tolerances.

FAQ's of ROUGHNESS COMPARATOR:

Q: How do I use the Roughness Comparator for surface finish assessment?

A: To use the comparator, simply place the machined part near the relevant reference strip, then visually and tactilely compare the surface finish of your sample with the standard strips on the device. Select the closest match to assess the surface roughness according to the Ra scale provided.Q: What types of machining finishes does this set include?

A: The comparator set includes standards for turning, milling, and grinding finishes, covering a broad range of industrial applications for quality control and inspection across different machining processes.Q: When should I use a roughness comparator in my workflow?

A: It is best utilized during or after machining operations for quick quality checks, process validation, or during final inspection stages. It is also valuable for rapid on-site verification during machine setup or maintenance.Q: Where can I use this roughness comparator?

A: The comparator is suitable for use in various industrial settings, such as manufacturing floors, workshops, quality control labs, and maintenance facilities. Its portability also makes it convenient for field inspections.Q: What is the process of comparing surface finishes with this tool?

A: The process involves manually matching your workpiece's finish with the closest reference strip by visual and tactile examination. The comparator provides immediate feedback, eliminating the need for electronic measurements or power supply.Q: What are the key benefits of using this device?

A: Major benefits include quick and accurate surface finish comparisons, portability, ease of handling, and suitability for use in environments with wide temperature or humidity ranges. Its compliance with international standards ensures reliable results for industrial quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 13 PRECISION & TESTING INSTRUMENTS Category

Holiday Detector

Application : Detecting pinholes, cracks, and coating discontinuities in protective coatings

Control Mode : Manual

Usage : For detection of holidays (defects) in coatings on pipelines, tanks, etc.

Features : Lightweight, Portable, Adjustable Voltage, AudioVisual Alarm

Accuracy : 5% of set value

Weld Inspection Kit

Application : Weld quality inspection

Control Mode : Manual operation

Usage : For inspecting weld seams and ensuring quality

Features : Lightweight and durable case multiple measurement tools

Accuracy : High precision measurement tools included

Vibration Meter

Application : Measuring vibration levels of machinery

Control Mode : Manual

Usage : Industrial and maintenance applications

Features : Compact portable design

Accuracy : 0.02 mm/s

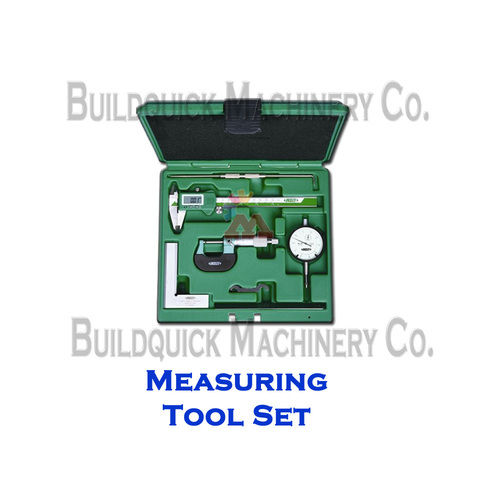

Measuring Tool Set

Application : Laboratory

Control Mode : Manual

Usage : Industrial

Features : High Accuracy

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS