Roughness Comparator

Roughness Comparator Specification

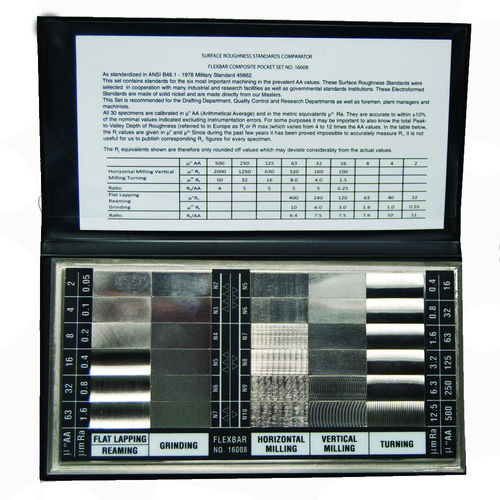

- Number of Specimens

- 12 to 30 comparators or patches (Varies by model)

- Features

- Corrosion-resistant, easy to handle, portable

- Response Time

- Immediate (Manual)

- Mounting Type

- Handheld or tabletop

- Test Range

- 0.4 to 6.3 m Ra

- Equipment Type

- Surface Roughness Comparator

- Display Type

- Visual Reference (No electronic display)

- Hardness

- Specimen Material Dependent (Typically Stainless Steel/Bronze)

- Max Height

- Plate thickness ~6 mm

- Resolution

- Sample class dependent

- Temperature

- 10C to 40C Operating Range

- Application

- Reference and visual/tactile comparative roughness evaluation

- Automation Grade

- Manual

- Specimen Size

- Each patch approx. 15 mm x 20 mm

- Power Supply

- Not Required (Manual)

- Humidity

- <80% RH (Non-Condensing)

- Measuring Range

- 0.4 m to 6.3 m Ra

- Accuracy

- Standardized per DIN, ISO, JIS or equivalent

- Usage

- Comparative standard for roughness inspection

- Capacity

- Varies as per number of sample patches

- Machine Weight

- Approx. 200 g (Comparator Plate)

- Test Speed

- Manual use

- Test Width

- Varies by sample area, typically up to 30 mm

- Control Mode

- Manual

- Number of Roughness Grades

- Usually 4, 12, or 30 (according to model)

- Finish Analysis Method

- Visual and tactile (touch/feel/manual comparison)

- Dimensions

- Approx. 100 mm x 50 mm x 3 mm

- Included Accessories

- Protective Case, Documentation/Reference Chart

- Surface Types Available

- Machined, Milled, Ground, Turned, and more

- Typical Use Industries

- Automotive, Manufacturing, Quality Control, Metalworking

- Material

- Hardened Steel Comparator Plate

About Roughness Comparator

Simplified Use and Broad Application Areas

To use the Roughness Comparator, align the sample area with the comparator plate, then visually and tactilely compare surface roughness. Its versatility fits a wide range of application areas: automotive engineering, metalworking shops, manufacturing plants, and quality control labs. This equipment type excels as a handheld or tabletop comparative standard, ideal for routine inspections. Its manual, easy-to-handle design guarantees accurate roughness evaluation even in challenging work environments.

FOB Port Details, Packaging, and Export Market Reach

FOB port charges are calculated precisely, and the Roughness Comparator is securely packagedenclosed in a robust protective case with complete documentation and a reference chart. Once your order is processed and the conditions are met, the comparator is carefully handed over for international export. India serves as a principal export market, with distributors, manufacturers, and service providers ensuring smooth shipment transitions to global destinations.

FAQs of Roughness Comparator:

Q: How do you use a Roughness Comparator for surface evaluation?

A: Simply place the comparator plate next to your test surface, and use visual and tactile (touch/feel) comparison to determine the closest roughness match. No electronic display or power is needed, making the process immediate and straightforward.Q: What types of surfaces can this Roughness Comparator evaluate?

A: The comparator is designed for machined, milled, ground, turned surfaces, and more. It covers a test range from 0.4 to 6.3 m Ra, matching the typical needs of metalworking, automotive, and manufacturing industries.Q: Where is the Roughness Comparator particularly beneficial?

A: Its widely used in quality control labs, automotive workshops, manufacturing environments, and any industrial setting where surface finish standards are critical for product performance and compliance.Q: When should I perform roughness comparison in my process?

A: Roughness evaluation should be conducted during intermediate or final inspections to ensure that surface finish specifications are met before assembly, shipping, or further processing.Q: What accessories come included with the Roughness Comparator?

A: Each set features a protective case, complete documentation, and a reference chart to support precise, reliable usage and safe storage.Q: How does the comparator maintain accuracy under different operating conditions?

A: Manufactured from corrosion-resistant materials, it performs consistently within a 10C to 40C range and up to 80% relative humidity, maintaining measurement precision based on standardized calibrations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 13 PRECISION & TESTING INSTRUMENTS Category

ROUGHNESS COMPARATOR

Application : Industrial

Usage : Surface roughness reference/comparison

Control Mode : Manual

Display Type : Physical surface blocks/plates

Equipment Type : Roughness Comparator

Mounting Type : Handheld

Clamp Meter

Application : Measuring AC voltage, current, continuity, resistance

Usage : Electrical Testing

Control Mode : Manual

Display Type : LCD Digital

Equipment Type : Clamp Meter

Mounting Type : Handheld

Combination Square Set

Application : Marking, Measuring & Layout in Woodworking, Metalworking, and Construction

Usage : Precision Measurement, Angle Marking, Depth Measuring

Display Type : Analog (etched graduations)

Equipment Type : Combination Square Set

Mounting Type : Handheld

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS