Top Cut

Price 100-800000 INR/ Unit

Top Cut Specification

- Surface

- Painted

- Lifting Height

- 1000 mm

- Motor Power

- 4 kW

- Lifting Speed

- 0.8 m/min

- Product Type

- Hydraulic Top Cut

- General Use

- Panel Processing

- Material

- Steel

- Type

- Industrial Cutting Machine

- Capacity

- 2500 kg

- Weight (kg)

- 900 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- PLC Control

- Cooling System

- Air Cooling

- Method

- Hydraulic

- Voltage

- 380 V

- Dimension (L*W*H)

- 3200 x 1000 x 1600 mm

- Feature

- High Precision, Durable, Low Maintenance

- Color

- Blue-Grey

- Operation Mode

- Foot Pedal/Hand Lever

- Noise Level

- 75 dB

- Frequency

- 50 Hz

- Blade Material

- High-Speed Steel (HSS)

- Application

- Sheet Metal Cutting, Fabrication

- Safety Features

- Emergency Stop, Safety Guard

- Oil Tank Capacity

- 60 Liters

Top Cut Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 5-6 Days

About Top Cut

Site Application and Material Features of Top Cut

Top Cut excels at panel processing, designed specifically for sheet metal cutting and fabrication tasks. Crafted with premium steel, the machine features high-speed steel blades suited to heavy-duty operations. It finds general use in various industrial settings where precision and reliability are paramount. The painted surface boosts durability, making it suitable for continuous operation in demanding environments, and the safety features ensure secure use at factories, workshops, and fabrication facilities.

Supply Ability, Delivery Time, and Dispatch Process

Top Cut is readily available for dispatching as per your project requirements. Our supply ability ensures prompt delivery with minimized wait times for arrival. Shipments depart from our primary FOB port in India, streamlining the valuation and logistics process. With proven distribution capability, businesses can expect seamless dispatch and timely arrival of machines, making your operation more efficient. Trust our experience for a smooth procurement from supply to installation.

FAQs of Top Cut:

Q: How does the Top Cut cutting machine enhance fabrication efficiency?

A: The Top Cut machine integrates a hydraulic cutting method and semi-automatic operation, allowing for rapid, precise panel processing in sheet metal applications. Its PLC control system and high-speed steel blades streamline workflow while maintaining high precision.Q: What safety features are included with the Top Cut?

A: Top Cut comes equipped with an emergency stop button and a robust safety guard. These features are designed to ensure operator security and reduce potential workplace hazards during operation.Q: When can I expect the Top Cut to be dispatched after purchase?

A: Upon successful purchase, dispatching occurs promptly in line with supply capacity. The typical lead time is minimized due to efficient processes and reliable distribution networks from our FOB port in India.Q: Where is the Top Cut most suitable for use?

A: Top Cut is best utilized in industrial fabrication settings such as manufacturing units, workshops, and panel processing facilities where precision and durability are essential.Q: What is the process for operating the Top Cut?

A: Operators can choose between the foot pedal and hand lever modes for flexible and controlled machine use. The semi-automatic system with PLC ensures easy operation while maintaining high production standards.Q: How does the cooling system contribute to machine durability?

A: The air cooling system efficiently regulates internal temperature during heavy usage, preventing overheating and contributing to the machines long-term durability and low maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 06 Scaffolding Products & Ladders Category

Prop Nut With Barrel

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Prop Nut With Barrel

Color : Other, Yellow, Galvanized finish

Feature : Corrosion resistance, High strength

Material : Other, Mild Steel

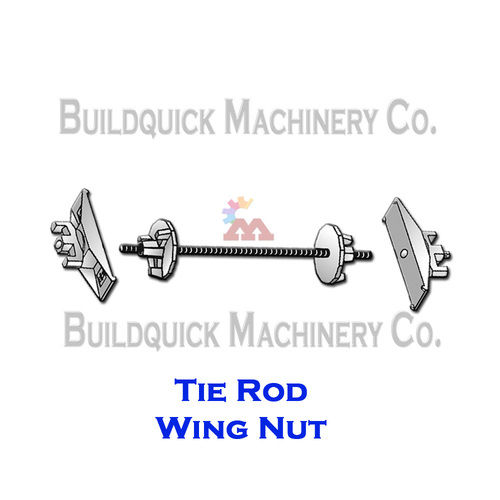

Tie Rod Wing Nut

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Tie Rod Wing Nut

Color : Other, Natural Metal / Silver Grey

Feature : Heavy Duty, Reusable

Material : Other, Cast Iron / Forged Steel

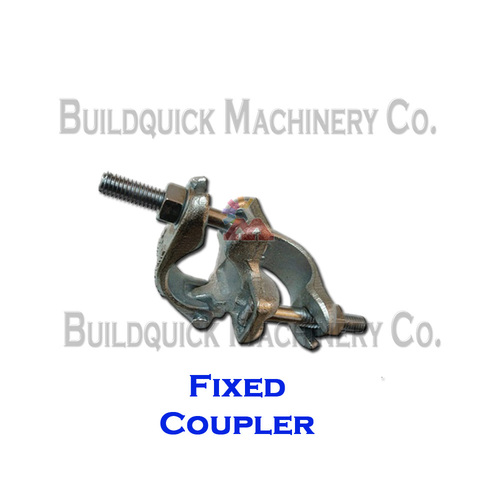

Fixed Coupler

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Fixed Coupler

Color : Other, Golden / Silver (Electroplated)

Feature : Rugged, Corrosion Resistant, Robust construction

Material : Other, Forged Steel

Board Retaining Coupler

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Board Retaining Coupler

Color : Other, Natural Grey / Zinc Coated

Feature : Durable, Corrosion Resistant, Easy to Install

Material : Other, Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS