Shutter Clamp

Price 100-800000 INR/ Unit

Shutter Clamp Specification

- Surface

- Galvanized

- Product Type

- Shutter Clamp

- General Use

- Construction Formwork

- Material

- Mild Steel

- Type

- Clamp

- Weight (kg)

- 0.6 - 1

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Method

- Formwork Fixing

- Dimension (L*W*H)

- Customized or Standard

- Feature

- Corrosion Resistant, Rugged Design

- Color

- Silver/Grey (Natural Metal Finish)

- Shape

- C-shaped/J-shaped

- Rust Proof

- Yes

- Tensile Strength

- High

- Finish Type

- Zinc Plated or Painted

- Manufacturing Process

- Forged/Pressed

- Customisation

- Available as per requirement

- Size Range

- 100mm to 300mm

- Packing Type

- Carton or Gunny Bag

- Application

- Building, Bridges, Walls, Columns

- Usage

- Securing shuttering panels in construction

- Load Bearing

- Up to 1 ton (depends on size)

Shutter Clamp Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 5-6 Days

About Shutter Clamp

Comprehensive Application & Unmatched Advantages

Shutter Clamps are engineered for formwork fixing across a spectrum of projects including buildings, bridges, columns, and walls. Widely used by professionals in construction sectors, these masterful clamps secure panels effortlessly. Their high tensile strength and rugged construction provide stability and unparalleled durability, ensuring the safety of structures. The must-have clamps shine in environments demanding robust solutions, proving vital for any construction expert seeking reliable and efficient panel securing mechanisms.

Certifications, Sample Policy, and Export Valuation

Each Shutter Clamp is delivered with certifications ensuring quality and reliability, meeting international construction standards. Sample policies allow distributors and service providers to assess products before full procurement, affording confidence in every shipment. Export markets are grandiose, with products shipped and valued across Asia, the Middle East, and Africa. The manufacturer prioritizes efficient delivery and maintains strong relationships worldwide, ensuring superior market presence and satisfaction with every purchase.

FAQs of Shutter Clamp:

Q: How do Shutter Clamps benefit construction projects?

A: Shutter Clamps provide high tensile strength and reliable performance, ensuring secure fixing of formwork panels in varied applications, including buildings and bridges. Their corrosion-resistant finish and rugged design enhance durability and safety for construction teams.Q: What is the process for customizing Shutter Clamps for specific requirements?

A: Customization is straightforward: clients specify dimensions, shape (C or J), load-bearing needs, and chosen finish. The manufacturer tailors the clamps accordingly, ensuring optimal fit and masterful performance for your project.Q: When should Shutter Clamps be procured for construction work?

A: It is ideal to procure Shutter Clamps during the planning phase to ensure timely delivery and readiness for panel securing throughout formwork fixing stages. Early procurement allows for customization and efficient workflow integration.Q: Where are Shutter Clamps commonly used?

A: Shutter Clamps are widely used at construction sites for buildings, bridges, walls, and columns, wherever formwork panels require secure anchoring and load-bearing capacity.Q: How does the rust proof feature enhance usage in construction?

A: The rust proof zinc plated or galvanized surface protects the clamp from corrosion, ensuring longevity and continual high performance even in harsh or outdoor construction environments.Q: What packing options are provided for delivered Shutter Clamps?

A: Shutter Clamps are packed in cartons or gunny bags, enhancing safety during shipment and making them both easy to transport and provided in excellent condition upon delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 06 Scaffolding Products & Ladders Category

Sacffolding and Ladder

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Yellow & Silver

Feature : Antislip steps, Foldable, Stable Base

Product Type : Scaffolding Ladder

General Use : Industrial, Construction, Maintenance

Gogo Clamp

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Silver / Metallic

Feature : Strong grip, corrosion resistant, easy to operate

Product Type : Gogo Clamp

General Use : Securing and fastening objects

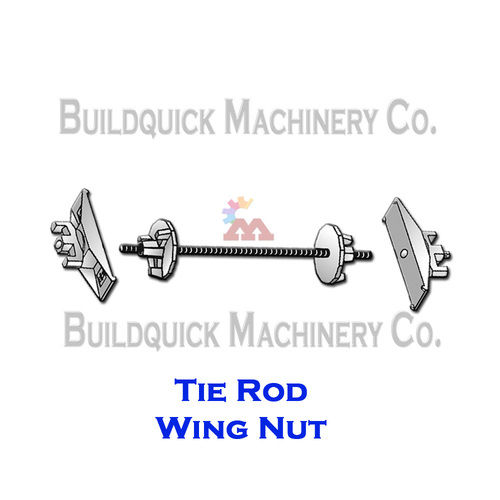

Tie Rod Wing Nut

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Natural Metal / Silver Grey

Feature : Heavy Duty, Reusable

Product Type : Tie Rod Wing Nut

General Use : Formwork Shuttering Accessory

Jack Nut

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Silver/Metallic

Feature : Corrosion resistance, antirotation design, quick installation

Product Type : Jack Nut

General Use : Fastening solutions, Structural assembly, Sheet metal applications

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS