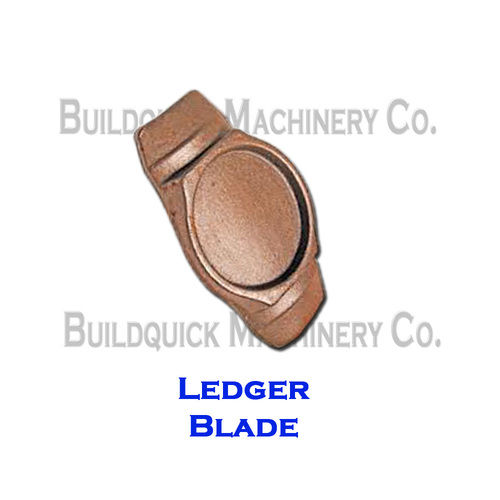

Ledger Blade

Price 100-800000 INR/ Unit

Ledger Blade Specification

- Surface

- Galvanized

- Product Type

- Ledger Blade

- General Use

- Scaffolding, Construction Support

- Material

- Mild Steel

- Type

- Ledger Blade

- Weight (kg)

- Approx. 0.7 to 1.0

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Method

- Hot Rolled

- Dimension (L*W*H)

- Standard: 85mm x 45mm x 5mm

- Feature

- Corrosion Resistant, Durable

- Color

- Silver, Metallic

Ledger Blade Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 5-6 Days

About Ledger Blade

Competitive Advantages and Applications of Ledger Blade

Ledger Blades deliver exceptional durability and corrosion resistance, offering a competitive advantage in demanding scaffolding and construction environments. Their robust design supports high-load applications, making them ideal for both residential and commercial projects. Frequently used in scaffolding systems for secure connections, these blades adapt seamlessly across a variety of application media. Additional uses include bridge repair, facade construction, and temporary structural supports, making them a versatile asset in multiple sectors.

Ledger Blade: Export Markets, Certifications, and Packaging

With a strategic FOB port in India, Ledger Blades reach both Premium domestic and overseas markets, catering to contractors and distributors worldwide. These blades are meticulously packaged-bundled or loose-to meet diverse customer requirements. Backed by recognized certifications, Ledger Blades assure consistent quality for every shipment. Their widespread acceptance across key export markets testifies to the product's reliability and compliance with international standards, solidifying their status as a preferred scaffolding component.

FAQ's of Ledger Blade:

Q: How is the Ledger Blade used within scaffolding systems?

A: The Ledger Blade is utilized as a crucial connection part in scaffolding systems, providing stable links between horizontal and vertical components to enhance overall structural integrity and safety during construction projects.Q: What benefits does a hot dip galvanized finish offer for Ledger Blades?

A: Hot dip galvanizing delivers superior corrosion resistance, extending the Ledger Blade's lifespan under harsh outdoor conditions and maintaining durability even in demanding environments.Q: When should I consider customizing the length of a Ledger Blade?

A: Customizing the length-options ranging from 600mm to 2000mm-is recommended when your project requires precise scaffolding dimensions or unique support configurations for specialized structures.Q: Where are Ledger Blades most commonly supplied from?

A: Ledger Blades are supplied by reputable manufacturers, distributors, and service providers based in India, serving both domestic and international construction markets.Q: What is the manufacturing process for Ledger Blades?

A: Ledger Blades are precision engineered using hot rolling methods, ensuring exact dimensions, high tensile strength, and a flawless finish.Q: How recyclable are the Ledger Blades?

A: Manufactured from mild steel, Ledger Blades are fully recyclable, promoting sustainability and effective material management across project life cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 06 Scaffolding Products & Ladders Category

Top Cut

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : PLC Control

Automatic : Other, SemiAutomatic

Material : Steel

Sacffolding and Ladder

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Manual

Automatic : No

Material : Other, Mild Steel, Aluminum

Gogo Clamp

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Other, Manual Operation

Automatic : No

Material : Other, Alloy Steel

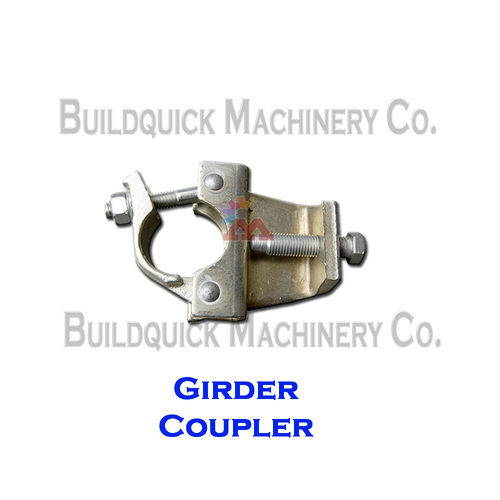

Girder Coupler

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Manual

Automatic : No

Material : Other, Forged Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS