Concrete Wiegh Batcher

Price 100-800000 INR/ Unit

Concrete Wiegh Batcher Specification

- Motor Power

- 2 HP Electric Motor

- Surface

- Powder Coated

- Lifting Speed

- 8-12 m/min

- Lifting Height

- Up to 10 m

- Product Type

- Weigh Batcher

- General Use

- Construction Site Concrete Mixing

- Material

- Mild Steel

- Type

- Mechanical

- Capacity

- 250 Kg/Batch

- Weight (kg)

- Approx 350 Kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual Lever Operated

- Cooling System

- Air Cooled

- Method

- Weigh Batching

- Voltage

- 220-240 V AC

- Dimension (L*W*H)

- 2000 x 700 x 1600 mm

- Feature

- Robust Construction, Accurate Measurement, Easy Mobility, Rust Proof

- Color

- Blue / Yellow

- Accuracy

- ± 2% of Weight

- Mobility

- Fitted with Pneumatic Tyres for Easy Moving

- Operating Handle

- Ergonomic Handle for Simple Operation

- Application

- Ideal for Small to Medium Construction Projects

- Discharge Mechanism

- Hand Lever Operated with Spring Back

- Finish

- Smooth Finish with Rust Resistant Coating

- Batch Hoppers

- 2 Nos. (One for Sand & One for Aggregate)

- Chassis

- Heavy Duty Frame Mounted on Wheels

- Safety Feature

- Locking Mechanism to Avoid Overturn

Concrete Wiegh Batcher Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 5-6 Days

About Concrete Wiegh Batcher

Technical Specification

| Heavy Duty Robust Steel Chassis | 75 X 40 Channel. |

| Capacity | 500 Kg (250 Kg Each Hopper) |

| Wheels | MS Wheel 4 Nos. |

| Weighing System | Pan Weight Of 50 Kg And 100 Kg |

| Jockey Weight | 0 Kg To 50 Kg Each |

Precision Concrete Batching for On-Site Projects

Achieve highly accurate measurement and mixing with our mechanical Concrete Weigh Batcher, specifically designed for small to medium construction tasks. The dual batch hoppers allow simultaneous workload handling for sand and aggregate, ensuring material consistency. The powder-coated finish delivers exceptional protection against corrosion, while the lockable discharge lever and ergonomic controls grant safe, simple, and smooth operation.

Built for Durability and Mobility

Mounted on a heavy-duty frame with pneumatic tyres, this batcher is engineered for mobility across challenging site terrains. The robust construction ensures stability, and the rust-proof coating increases its lifespan, even in demanding outdoor environments. Whether youre a supplier, manufacturer, or contractor, this mobile solution fits seamlessly into various construction workflows.

FAQs of Concrete Wiegh Batcher:

Q: How does the concrete weigh batcher improve mixing accuracy on construction sites?

A: This batcher features two dedicated hoppers for sand and aggregate, with accuracy maintained to within 2% of the measured weight. It prevents material wastage and guarantees consistent mix proportions for every batch, resulting in higher quality concrete.Q: What is the process of operating the weigh batcher and lifting mechanism?

A: Users load each material into respective hoppers, set the desired weight using the manual lever, and operate the hand lever to discharge ingredients. A 2 HP electric motor powers the lifting, raising batches up to 10 meters at speeds of 8-12 m/min. Safety features include a spring-back lever and locking mechanisms for controlled operation.Q: When is this batcher most beneficial on-site?

A: It is ideally suited for small to medium construction projects where on-site mixing and accurate material measurement are essential for reliable concrete quality and workflow efficiency.Q: Where can the weigh batcher be relocated during construction work?

A: Thanks to its heavy-duty chassis mounted on wheels with pneumatic tyres, it can be moved smoothly across uneven ground and different site locations, providing flexible and convenient access as required.Q: What safety measures are incorporated in the product design?

A: The weigh batcher includes a locking mechanism to prevent accidental overturn during discharge, a spring-back hand lever for controlled material flow, and an ergonomic handle to reduce operator fatigue and enhance safe handling.Q: How does the batchers rust-resistant finish contribute to its longevity?

A: The powder-coated, rust-resistant surface protects the mild steel body from corrosion and environmental wear, ensuring long-term performance and reliability in various climatic conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 05 Material Handling Equipments Category

Mast Climbing Work Platform

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Blue / Yellow or as required

Voltage : 380V / 50Hz, 3 Phase

Computerized : No

Weight (kg) : Approx. 40007000 kg (depending on configuration)

Rack & Pinion Hoist

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Yellow / Custom

Voltage : 380V/415V, 3 Phase

Computerized : No

Weight (kg) : 3200 kg

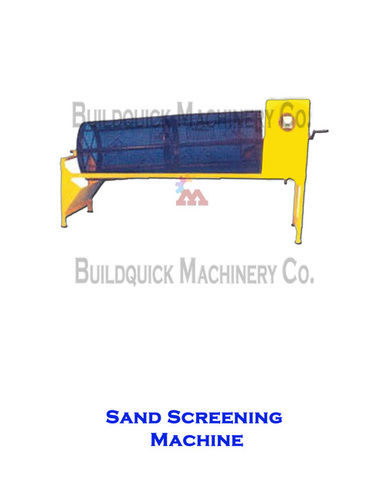

Sand Screening machine

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Yellow/Blue

Voltage : 220240 V AC

Computerized : No

Weight (kg) : 370 kg

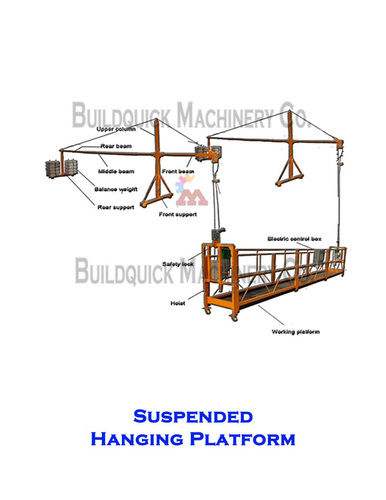

Suspended Hanging Platform

Price 100-800000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Orange / Silver / Custom

Voltage : 220V / 380V, 5060Hz

Computerized : No

Weight (kg) : approx. 1800 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS