Bitumen SPrayer

Price 100-800000 INR/ Unit

Bitumen SPrayer Specification

- Motor Power

- 10 HP Diesel Engine

- Surface

- Painted / Anti-Corrosive Coating

- Product Type

- Mobile Bitumen Sprayer

- General Use

- Bitumen Spraying for Road Construction

- Material

- Mild Steel

- Type

- Truck Mounted

- Capacity

- 4000 Litre

- Weight (kg)

- 2500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/Valve Operated

- Cooling System

- Air Cooled

- Method

- Spray Application

- Voltage

- 12 Volt (for Controls and Ignition)

- Dimension (L*W*H)

- 5000 mm x 2500 mm x 2100 mm

- Feature

- Uniform Spraying, Efficient Heating, User Friendly Controls

- Color

- Black & Yellow

- Pump Type

- Rotary Gear Pump

- Chassis

- Heavy Duty Structural Steel

- Pressure Gauge

- Included

- Tyres

- Heavy Duty Pneumatic

- Fuel Tank Capacity

- 120 Litres

- Spraying Width

- 2.5 meters

- Spray Bar Length

- 2.4 meters (expandable)

- Burner Type

- Diesel Fired

- Towing Arrangement

- Provided with Adjustable Towbar

- Nozzle Controls

- Individual Shut-off

- Safety Devices

- Fire Extinguisher and Emergency Stop

- Heating System

- Automatic Thermostat Control

- Tank Insulation

- Glass Wool Layer

- Road Speed

- Up to 40 km/h

- Hose Pipe

- 10 meters with Nozzle

Bitumen SPrayer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 5-6 Days

About Bitumen SPrayer

Technical Specification

- Capacity : 4 T/ 6 T/ 8 T / 10 T / 12 T

- Shape : Oval

- Insulation : 50 Mm Thick With Glass Wool

- Temp. Gauze : 0-300o C

- Main Hole : 450 Mm In Diameter

- Mounting Tank Mounted On Any Suitable Truck Chassis

- Spray Bar

- Length : 2.4 Meters

- Length With Extension : 4.17 Meters

- Spraying Width : 4.5 Meters

- Control Of Spray

- Bar

- Fully Circulation Of Pre-Heated Bitumen

- Bitumen Spraying Pressure : 0-5 Kg./ Cm2

- Bitumen Pump : 2 X 2 Size Positive Displacement Gear Pump With Output Of 450 Liters/ Min.

- Air Compressor Standard Make 2 Cylinder

- Air Compressor Burner

- Fuel Consumption : 7-8 Liters/ Hour

- Engine Fuel Tank Capacity : 50 Liters

- Burner Fuel Tank Capacity : 100 Liters

- Engine Kirloskar Make 25 HP@2000 Rpm Air Cooled Diesel Engine.

Efficient Heating and Uniform Application

Equipped with a diesel-fired burner and glass wool insulation, the bitumen sprayer ensures rapid, energy-efficient heating. The automatic thermostat control maintains a consistent temperature, optimizing bitumen viscosity for flawless spray application. The expandable spray bar and rotary gear pump guarantee uniform spreading over large road surfaces, improving work quality and reducing material wastage.

Heavy Duty Construction, User-Friendly Operation

Manufactured from robust mild steel with an anti-corrosive coating, this sprayer is built for durability in challenging environments. The semi-automatic, manual/valve-operated controls enhance usability, while safety mechanisms like an emergency stop and fire extinguisher provide secure operation. The heavy-duty steel chassis, pneumatic tyres, and towing arrangement make transportation and field deployment easy across road construction sites.

FAQs of Bitumen SPrayer:

Q: How does the diesel-fired heating system work in this bitumen sprayer?

A: The sprayer uses a diesel-fired burner integrated with an automatic thermostat control. This system heats the bitumen in the insulated tank efficiently, maintaining the desired temperature for consistent spraying without manual intervention.Q: What materials and roads can this sprayer be used on?

A: This sprayer, constructed from mild steel and featuring user-friendly nozzle controls, is suitable for road construction projects requiring uniform bitumen application. Its design supports use on highways, municipal roads, and road maintenance works across India.Q: Where is the bitumen sprayer typically deployed and transported?

A: The sprayer is truck mounted and comes with a heavy-duty chassis and adjustable towbar, making it easy to transport to different construction locations. It is also equipped to achieve road speeds up to 40 km/h for quick repositioning.Q: What is the process of operating the sprayer for uniform application?

A: Operation involves heating the bitumen with the diesel-fired system, adjusting spray bar length as needed, and using the manual/valve-operated controls to regulate spray width and pressure. Nozzle controls allow for individual shut-off, facilitating precise and uniform coverage.Q: When should the fire extinguisher and emergency safety devices be used?

A: The included fire extinguisher and emergency stop safety devices are to be used in case of fire hazards or when immediate equipment shutdown is required. Their presence ensures operator safety during high-temperature operations.Q: What benefits does glass wool insulation provide for the tank?

A: Glass wool insulation keeps the tank thermally efficient, minimizing heat loss and maintaining optimal bitumen temperature throughout the spraying process. This results in energy savings, reduced operational time, and enhanced performance during work.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in 03 CONCRETE VIBRATORS Category

High Frequency Vibrator

Surface : Smooth Finish

Product Type : High Frequency Vibrator

Color : Other, Yellow and Black

Method : Other, Vibration

General Use : Concrete Compaction

Material : Metal and Plastic, Other

Concrete Vibrator

Surface : Smooth Surface Finishing

Product Type : Concrete Vibrator

Color : Red

Method : External Vibration, Other

General Use : Concrete Vibrating

Material : Metal, Other

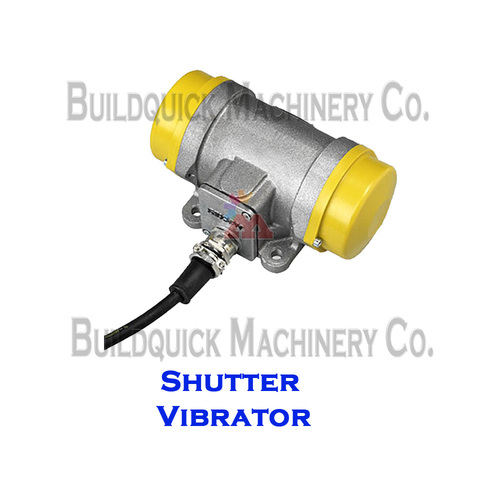

Shutter Vibrator

Surface : Smooth finish

Product Type : Shutter Vibrator

Color : Other, Yellow and Silver

Method : Other, Vibration

General Use : Concrete Shuttering Vibrations

Material : Other, Metal

Diesel Engine Needle Vibrator

Surface : Painted

Product Type : Diesel Engine Needle Vibrator

Color : Red

Method : Mechanical, Other

General Use : Construction and Concrete Vibrating

Material : Other, Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS